GYFTY53 Fiber Optic Cable (Direct buried)

GYFTY53 Fiber Optic Cable Single Armor Double Jackets Stranded Loose Tube FRP Strength Member Waterproof Outdoor Cable

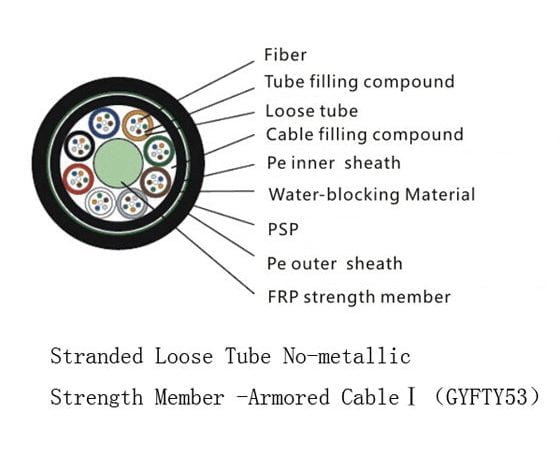

GYFTY53 Fiber Optic Cable (Direct buried) Single Armor Double Jackets Stranded Loose Tube FRP Strength Member Waterproof Outdoor Cable use Fiber Reinforced Plastic as central strength member to provides anti-electromagnetic interference property. It has good mechanical properties and resist to electromagnetic interference The armor structure helps to protect the cable from rat bite and moisture proof. Double-jacket structure make cable have nice properties of moisture resistance and crush resistance. A layer of water-blocking material is applied around the cable core to prevent water ingress.

GYFTY53 Fiber Optic Cable Single Armor Double Jackets Stranded Loose Tube FRP Strength Member Waterproof Outdoor Cable

GYFTY53 Fiber Optic Cable (Direct buried) Fiber Type: OS2 9/125 G652D /OM1 62.5/125μm Multimode – OM2 50/125μm Multimode – 10G OM3 50/125μm Multimode – 10G OM4 50/125μm Multimode (Other Fiber available Too)

The GYFTY53 Fiber Optic Cable (Direct buried) is constructed by inserting a 250um fibers into a loose tube made of a high-modulus material filled with a water-resistant compound.A Fiber Reinforced Plastic (FRP) locates in the center of core as a non-metallic strength member. The tubes (and fillers) are stranded around the strength member into a compact and circular core. Then the cable core is covered with a thin polyethylene (PE) inner sheath, which is filled with jelly to protect it from water ingress. A layer of water-blocking material is applied around the cable core to prevent water ingress all the same. After a corrugated steel tape armor is applied. the cable is completed with a PE outer sheath.

Features of GYFTY53 Fiber Optic Cable (Direct buried):

– Good mechanical and temperature performance.

– Special control of exceed length and layer stranding technology.

– Low attenuation and dispersion.

– Single armor and double sheath providing excellent crush resistance, water proof, and avoiding rat bite.

– FRP (non-metallic) Strength Member ensures good anti-electromagnetic interference.

– Stranded loose tube improves the tensile strength.

– Water -blocking material enhances water-blocking & moisture-proof.

– Friction reduction because the tube filling compound ensures a critical protection of the fiber.

– Double sheath design enhancing the crushing performance, good moisture-resistance, ultra violet radiation resistant.

Application:

– Frequent lightning area and anti electric field : The subway, tunnel

– Long-distance communication: Local trunk network & User network

– Duct and direct buried application

– Harsh environment

GYFTY53 Fiber Optic Cable (Direct buried)