What Is Preshrunk Fiber Fusion protection sleeve ?

TOP Quality,100% Real Preshrunk type Fiber Optic Fusion Splice Protection Sleeves,Clear.304 High Grade stainless steel needle,Polished, Buffer Free, No hurt fibers.Multiple size optional, Huge stock, Fast Shipping and Fast Delivery. OEM & ODM,Custom made,Factory Wholesale Price.

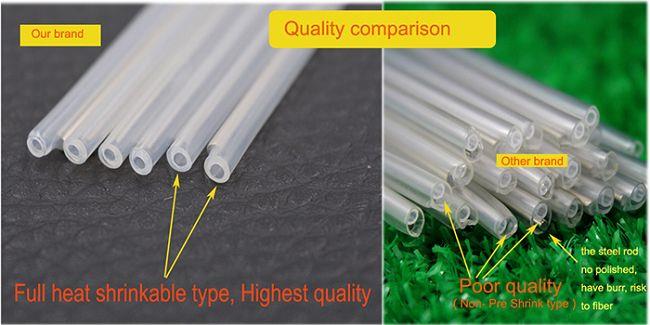

The Preshrunk Series are Top quality and long-term reliability Fibre Fusion Splice Protector Sleeves. 100% Imported high quality 304 grade stainless steel needle, not demistic material. No rust in one life. Single holed ends eliminates improper fiber threading .its quality is much more excellent than ordinary one at marketing

Key Features

1. The Preshrunk configuration is an excellent design which can make the single holed ends eliminates improper fiber threading, and steel needle never fall out.

2. Smooth deburred stainless steel reinforcing member ends decrease the risk of fiber damage during installation.

3. Strength member is made from “Full hard” stainless steel of pure 304 high grade 100% imported (not demestic,poor quality 304) and is ground at the edges before polishing to make it completely burr free to avoid rupturing during shrinking. Pure 304 grade gives better corrosion resistance, No rust in one life. even in coastal environment. Resistant to heat shocks, no cracking dripping or flowing.

4. Air proof configuration keeping the splice point’s good resistance of humidity and temperature.Extended liner length prevents contact between the fiber and the backbone.

5. Top Quality and Super High Performance, 5 years warranty.

Material specifications:

1. Application Type: Single Fiber 250/900µm

2. Compatibility: Most splice trays, ovens and coated fibers

3. Outer Material: Cross-linked Polyolefin Heat Shrinkable Tubing +135°C MIL Spec.

4. Inner Material: Hot-melt adhesive Ethylene Vinyl Acetate (EVA) Copolymer

5. Reinforcing Pin: Stainless Steel 304 with polished and rounded edges

6. Colours: Clear for easy visual inspection

7. Splice Operating Temperature: -40°C to +70°C (Heat shrink outer rated at -55°C to +135°C)

8. Storage Temperature: -40°C to +70°C

9. Package Quantity: Bags of 100pcs. 500pcs/large bag.

Construction:

Our fiber optic fusion splice protector sleeves are manufactured pre-shrunk in a heat-bonded assembly that consists of three components:

● An inner tube of hot-meltable adhesive

● An outer of heat-shrinkable tubing

● A reinforcing strength member

The hot-melt adhesive inner tube bonds to both the fiber and the heat shrinkable outer tube to encapsulate the fusion splice joint and provides vibration damping and an environmental seal, protecting the fiber from damage and contaminants.

The outer high quality irradiation cross-linked polyolefin heat shrinkable tubing provides an instant shrink-force and drives the adhesive liner into all areas of the splice and excludes all the air.

Reviews

There are no reviews yet.