Fiber Optic Splitters

Fiber Optic Splitters

fiber optic splitter is a passive optical component that is used in fiber optic networks to split a single incoming optical signal into multiple outgoing signals. It is essentially a device that takes an optical signal and divides it into two or more separate signals, allowing a single optical fiber to serve multiple end points.

Fiber optic splitters are commonly used in passive optical networks (PONs) to distribute signals to multiple end users. They can be used to connect multiple devices to a single fiber optic line, such as in a fiber to the home (FTTH) network where multiple households are connected to a single fiber optic cable.

There are different types of fiber optic splitters, including fused biconical taper (FBT) splitters and planar lightwave circuit (PLC) splitters. FBT splitters are made by fusing and stretching two or more fibers together, while PLC splitters use a flat waveguide made of silica or other materials to split the signal.

Fiber optic splitters are important components in fiber optic networks because they allow a single optical fiber to be used to serve multiple users or devices. Without splitters, it would be necessary to run a separate optical fiber to each end point, which would be expensive and impractical in many situations.

Fiber optic splitters can be used in a variety of applications, including telecommunications, cable TV, and internet service provider (ISP) networks. They are often used in passive optical networks (PONs), which are a type of fiber optic network that does not require active components like repeaters or amplifiers.

The two most common types of fiber optic splitters are FBT and PLC splitters. FBT splitters are made by fusing and stretching two or more fibers together, and are relatively simple and inexpensive to manufacture. However, they are limited in terms of the number of splits they can support, typically up to 1:32.

PLC splitters, on the other hand, use a flat waveguide made of silica or other materials to split the signal. They are more complex to manufacture than FBT splitters, but they can support a larger number of splits, typically up to 1:64 or higher. PLC splitters are also more reliable and offer better performance in terms of insertion loss and wavelength uniformity.

In summary, fiber optic splitters are essential components in fiber optic networks that allow a single optical fiber to serve multiple end points. They come in different types, with different advantages and limitations, and are used in a variety of applications including telecommunications, cable TV, and ISP networks.

There are several different models of fiber optic splitters available on the market, but the two most common types are fused biconical taper (FBT) splitters and planar lightwave circuit (PLC) splitters.

FBT splitters are made by fusing and stretching two or more fibers together. The fibers are aligned so that light entering one fiber is split between the output fibers in a predetermined ratio. FBT splitters are relatively simple and inexpensive to manufacture, but they are limited in the number of splits they can support, typically up to 1:32.

PLC splitters, on the other hand, use a flat waveguide made of silica or other materials to split the signal. The waveguide is etched with a series of trenches or ridges that split the signal into multiple outputs. PLC splitters can support a larger number of splits than FBT splitters, typically up to 1:64 or higher, and offer better performance in terms of insertion loss and wavelength uniformity. However, they are more complex and expensive to manufacture than FBT splitters.

Other types of fiber optic splitters include tree and star couplers, which are used in some specialty applications, as well as wavelength division multiplexing (WDM) splitters, which are used to split optical signals into different wavelength bands for transmission over a single fiber. There are also variable optical attenuators (VOAs), which can be used to adjust the power level of an optical signal, and optical circulators, which can be used to route signals in different directions.

In summary, there are several different models of fiber optic splitters available, including FBT and PLC splitters, as well as other specialized types of splitters and related components. The choice of splitter model will depend on the specific application and performance requirements of the fiber optic network.

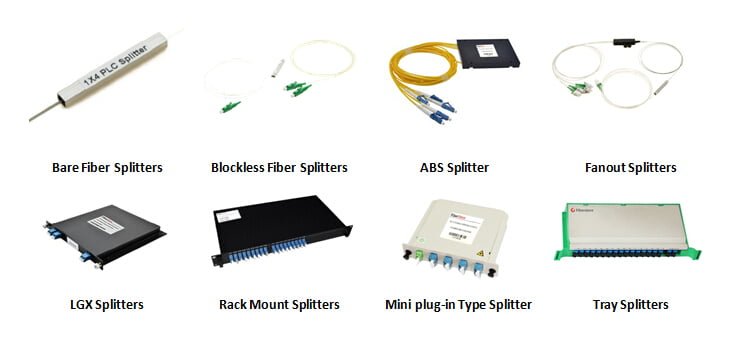

what are Fiber Optic Splitters different shape?

Fiber optic splitters come in different shapes and form factors, depending on the specific application and installation requirements. The most common shapes for fiber optic splitters include:

1-Box-type splitter: This is a type of splitter that is housed in a rectangular box, typically made of plastic or metal. The box contains the splitter components and is designed to be mounted on a wall or placed in a rack or cabinet.

2-Module-type splitter: This is a type of splitter that is designed to be installed inside a fiber optic patch panel or enclosure. The splitter components are contained in a module that can be easily inserted or removed from the patch panel or enclosure.

3-Bare fiber splitter: This is a type of splitter that does not have an outer protective housing or enclosure. Instead, the splitter components are exposed and are typically spliced directly onto the incoming and outgoing fiber optic cables.

4-Rack-mount splitter: This is a type of splitter that is designed to be installed in a standard 19-inch equipment rack. The splitter components are housed in a metal enclosure that can be easily mounted in the rack along with other networking equipment.

5-Tube-type splitter: This is a type of splitter that is housed in a cylindrical tube, typically made of plastic or metal. The tube contains the splitter components and is designed to be mounted on a wall or placed in a splice tray.

In addition to these common shapes, there are also specialized types of fiber optic splitters that are designed for specific applications or installation requirements. For example, there are splitters that are designed for outdoor use and are ruggedized to withstand harsh weather conditions, as well as splitters that are designed for use in high-density data centers or other environments where space is at a premium.