LC UPC 12 Fiber Pigtail Jacketed MM OM2 50/125 Orange 0.9mm

$12.00

LC UPC 12 Fiber Pigtail Jacketed MM OM2 50/125 0.9mm with competitive price.We supply quality LC UPC 12 Fiber Pigtail Jacketed MM OM2 50/125 0.9mm with 900um outer jacket. Ideal for fusion splicing.

What Is LC UPC 12 Fiber Pigtail Jacketed MM OM2 50/125 Orange 0.9mm?

LC UPC 12 Fiber Pigtail Jacketed MM OM2 50/125 10Gb Aqua 0.9mm with competitive price.We supply quality LC UPC 12 Fiber Pigtail Jacketed MM OM2 50/125 10Gb Aqua 0.9mm with 900um outer jacket. Ideal for fusion splicing.We also offer custom-made specification pigtails, please contact us for details.A fiber pigtail is a specific hardware connection used for cable termination. On a fiber pigtail, one end of the wire is simply exposed fiber and the other end has a per-installed connector on it. Fiber pigtails are commonly spliced onto individual strands of a multi-fiber trunk cable.

Pigtails. A fiber pigtail is a single, short, usually tight-buffered, optical fiber that has an optical connector per-installed on one end and a length of exposed fiber at the other end. The end of the pigtail is stripped and fusion spliced to a single fiber of a multi-fiber trunk.

Fiber optic pigtail is a fiber optic cable terminated with a factory-installed connector on one end, leaving the other end terminated. Hence the connector side can be linked to equipment and the other side melted with optical fiber cables.

Features of LC UPC 12 Fiber Pigtail Jacketed MM OM2 50/125 Orange 0.9mm:

1) Superior qualified standard PC, APC, UPC, SPC polishing;

2) 100% optic test: Insertion Loss: ≤0.3 (PC); ≤0.2 (APC); ≤0.2 (UPC); ≤0.3 (SPC);

3) 100% optic test: Return Loss: ≥45 (PC); ≥60 (APC); ≥55 (UPC); ≥50 (SPC);

4) φ0.9mm, φ2.0mm, φ3.0mm cable optional;

5) Single mode (9125) or multi mode (50/125 or 62.5/125) fiber available;

6) FC, SC, LC, MU, ST, MT-RJ, etc connector

7) Simplex and duplex connector available; 8) Good exchange ability and good durability;

9) Available in fiber bunch, ribbon fan-out, pigtail available;

10) Meets ISO9001, ROHS and Bell core GR 326-core standards;

11) Customized specifications are welcomed.

Applications LC UPC 12 Fiber Pigtail Jacketed MM OM2 50/125 Orange 0.9mm:

1) CATV, metro test equipment;

2) Telecommunication networks;

3) Local area networks (LAN);

4) Wide area networks (WAN);

5) Premise installations;

6) Data processing networks;

7) Video and military active device termination.

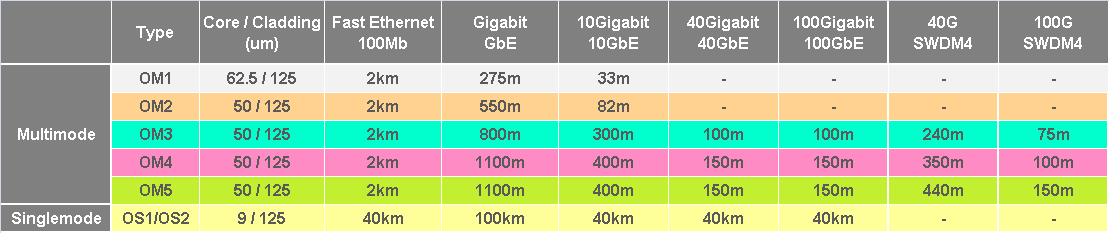

OM2 Fiber

Likewise, OM2 fiber also comes with an orange jacket and uses a LED light source but with a smaller core size of 50 µm. It supports up to 10 Gigabit Ethernet at lengths up to 82 meters but is more commonly used for 1 Gigabit Ethernet applications.

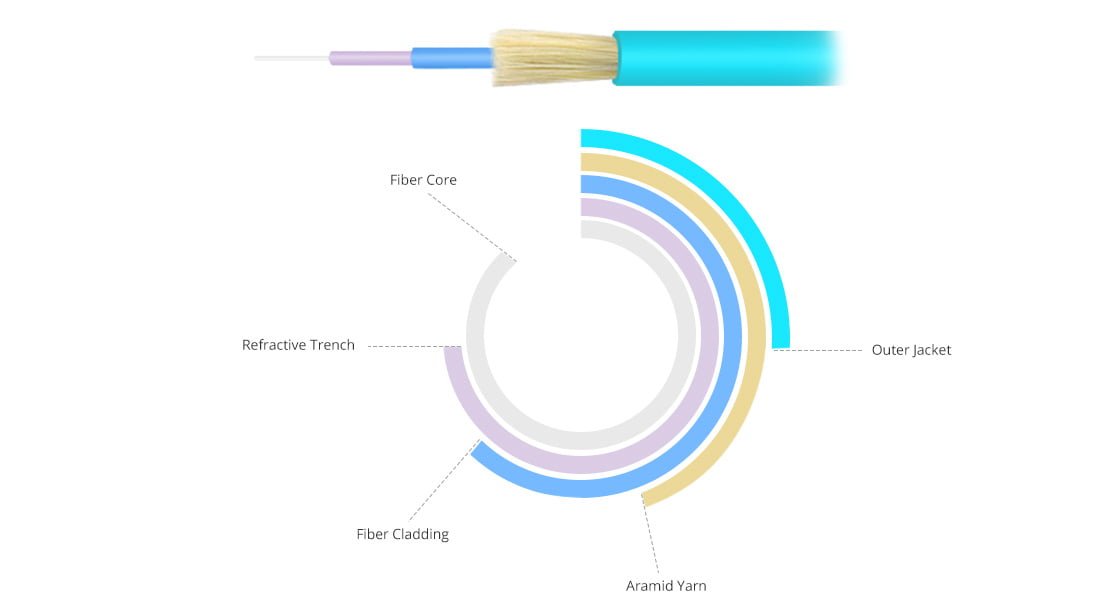

Bend Insensitive Fiber Optic Cable Structure

Bend Insensitive Fiber Optic Cable Structure A unique refractive trench with low refractive index glass layer in BIF, which reduces in light dispersion upon twisting and bending, ensuring network transmission stably and fast.

PVC Vs LSZH Vs OFNP Cable Jacket

PVC Vs LSZH Vs OFNP Cable Jacket

2.0mm vs 3.0mm Cable Diameter

2.0mm vs 3.0mm Indoor Fiber Optic Cable Diameter

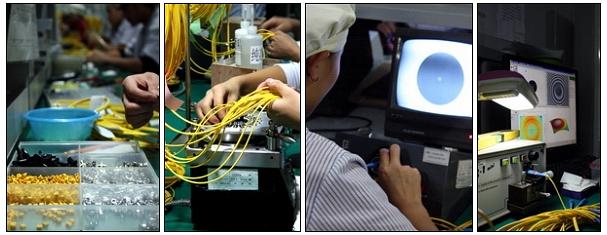

Quality production Stages For Fiber Optic Pigtail or Fiber Pigtail Assembly

So what should be taken into consideration when choosing a ‘good’ product? What are the features that one should look for that defines the quality of any connector or jumper assembly? In order to appreciate the significance of a standard compliant product, one must first understand the process of actually making an optical connector assembly and the potential problems that could occur at each of the stages.

Production Process Fiber Patch Cord or Fiber Optic Patch Cable or Fiber Optic jumper cables

There are three main processes in the termination of a Fiber Optic Pigtail or Fiber Pigtail Assembly, Preparation, Termination and Polishing and a total of 15 steps where negligence at any one of the steps will result in an inferior jumper assembly. Each process consists of small steps, and each step requires strict Quality Control of not only the equipment used, but also how each step is carried out.

preparation of fiber cable

- Stripping of outer cable jacket

- trimming of kevlar fibers to length

- Stripping of 900um buffer

- clean bare fiber

- check fiber for damage

- mix two part epoxy

- degas epoxy

- check ferule id

termination of fiber cable

- inject epoxy and insert fiber

- crimp kevlar to back post

- crimp outer jacket

- cure connector in oven

polishing of connector end face

- cleave fiber

- Remove excess epoxy by hand or machine

- polish end-face by grinding machine

Quality control steps

Comprehensive performance testing makes sure the cable work more secure and data transmission more reliable and stable in your network.

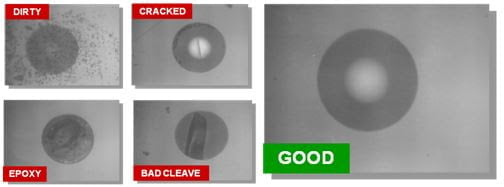

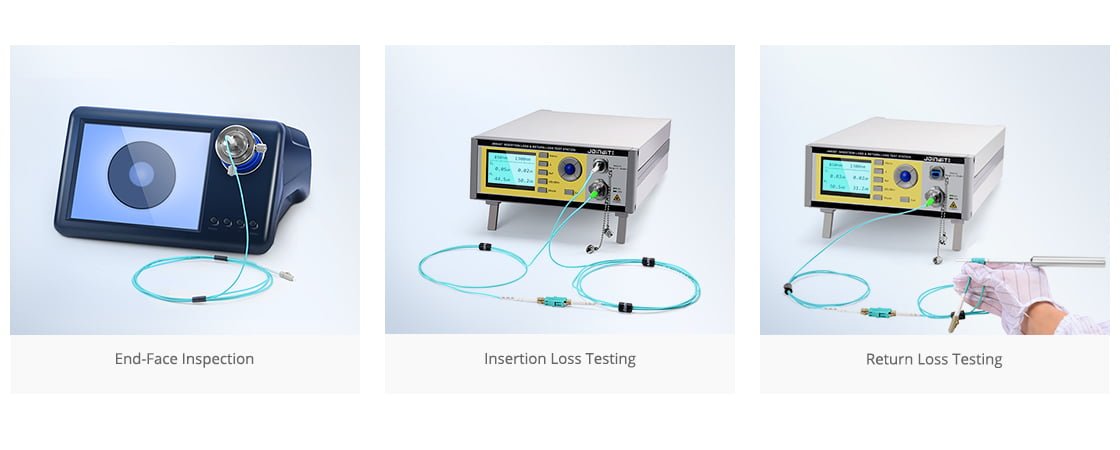

1-End-Face Inspection

Dirty Clean Fiber Optic Patch Cord

End-Face Inspection Evidently, fiber end-face defects like scratches, pits, cracks, and particle contamination will have a direct impact on the performance, contributing to poor insertion/return loss. Any irregularity that impedes light transmission from one fiber to the other will negatively affect IL and RL.Inspect the connector end face for scratches, defects and contamination to ensure reliable fiber connections.

2-Insertion Loss Testing

Insertion Loss Testing In telecommunications, insertion loss refers to the loss of signal power, calculated as a ratio in dB (decibel), resulting from inserting a device in a transmission line or optical fiber. It can also be referred to as attenuation, which indicates how much the signal loss is by comparing the input power to the output power. A lower insertion loss value indicates a better insertion loss performance. For example, an insertion loss of 0.3dB is better than 0.5dB.

3-Return Loss Testing

Return Loss Testing When a signal is transmitted through a transmission line, some signal power is always reflected or returned to the source due to discontinuities in the transmission line. The discontinuity can be a mismatch with the terminating load or with a device inserted in the line. Return loss refers to the loss of reflected signal power. Therefore, the higher the return loss is, the lower the amount of reflection will be. That is to say, the fiber connector will have better performance with a higher value of RL.

4-3D Interferometer Testing

3D Interferometer Testing Test connectors or ferrules of cables to ensure that radius of curvature, the apex offset and fiber height can meet and exceed industry standards.

How to Strip Fiber Optic Pigtail with Tri-Hole Fiber Stripper?

How to Strip Fiber Optic Pigtail with Tri-Hole Fiber Stripper

A Variety of Applications for Different Equipments

Widely used in CATV, FTTH/FTTX, telecommunication networks, premise installations, data processing networks, LAN/WAN network, and more.

Fiber Pigtail & Patch Cord Variety of Applications for Different Equipments

Mefiberoptic.com is one of the leading China manufacturers and suppliers providing you with LC UPC 12 Fiber Pigtail Jacketed MM OM2 50/125 Orange 0.9mm. Our factory has applied the most advanced equipment and technology to better serve you.

| Connector Type |

LC |

|---|---|

| Fiber Mode |

MultiMode |

| Fiber Type |

MM G651A1a 50/125 OM2 |

| Fiber Count |

12 Fiber |

| Cable Diameter |

0.9mm |

| Cable Length |

1m(3ft) ,2m(7ft) ,3m(10ft) |

| Polish Type |

UPC |

| Cable Jacket |

LSZH ,OFNP ,PVC |

| HS Code |

85367000 |

| Brand |

OEM |

3 reviews for LC UPC 12 Fiber Pigtail Jacketed MM OM2 50/125 Orange 0.9mm

Related products

FOCC

Your best partner For fiber optic products with 15 years of experience.Wholesale with competitive price and quality in China

Our Email:

Check our contact page

Our phone number:

+86-755 29360455

Our Address:

4th Floor, Building 1, YiJiaYang Science and Technology Park, No.159 HuaWang Road,Longhua District Shenzhen

Wilber –

Reliable performance, even in demanding environments, from these pigtails.

Zane –

High-performance pigtails, worth every penny.

Abigale –

High-quality pigtail materials and craftsmanship.