In the data center, copper patch panel is an ideal method to create a flexible, reliable and tidy cabling system. Today, various styles of copper patch panels can be found in the market, such as shielded or unshielded patch panel, flat or angled patch panel, etc. And the configurations can also be different from numbers of ports, such as 12-port, 24-port, 48-port patch panel, etc. So how to select the most suitable one for your applications?

What Is Copper Patch Panel?

Copper patch panel is designed for both shielded and unshielded copper cables like Cat5e, Cat6, Cat6a and Cat7. It is commonly used in a local area network (LAN) as a mounted hardware assembly that contains ports to connect and manage incoming and outgoing Ethernet cables. The network patch panel is typically made with 8-pin modular ports on one side and 110-insulation displacement connector blocks on the other side. Patch cables coming into the panel are terminated the insulation displacement connector. On the opposite side, the 8-pin modular connector plugs into the port which corresponds to the terminated wires. With the Ethernet patch panel, each pair of cables has an independent port. So copper patch panels offer simple and efficient interconnection in Ethernet applications.

Types of RJ45 Patch Panel

Cat5e Patch Panel

Cat5e patch panel is compliant with TIA/EIA 568 industry specifications and is used for high speed LAN transmission. Generally, this type of copper patch panel is available in 6-port and 8-port module groupings, in 8, 12, 24, and 48-port sizes. With numbers labeled on ports, it’s easy for cable organization. 24-port Cat5e patch panel is the most popular in the market, which has punch down and feed-through patch panel for customer choice. FS.COM Cat5e patch panels are made from steel materials so that they can stand up even the most extreme conditions. For more information about Cat5e patch panel, please refer to How to Wire Cat5e Patch Panels?

Cat6 Patch Panel

Cat6 patch panel is specially designed for use in Gigabit Ethernet applications. It also meets or exceeds the TIA/EIA 568 industry specification, and fits to use with different kinds of Cat6 cables and accessories. Besides, Cat6 patch panel features high-density and provides the performance needed for present and next generation data communications networks and applications. These high-density patch panels are available in 12-port, 24-port, 48-port versions, and feature enhanced front and rear labeling features for easy circuit identification.

Cat6a Patch Panel

Cat6a patch panel supports all performance requirements of IEEE 802.3an (10GBase-T) and TIA Augmented Category 6 (6a) cabling specifications without requiring the use of individual jacks for the panel termination. This RJ45 patch panel can be used to future-proof your network connection for 10 Gigabit Ethernet. And this Ethernet patch panel can be installed effortlessly in universal 19″ racks/cabinets, or wall mount brackets with 1U standard height.

Ports of Copper Patch Panel

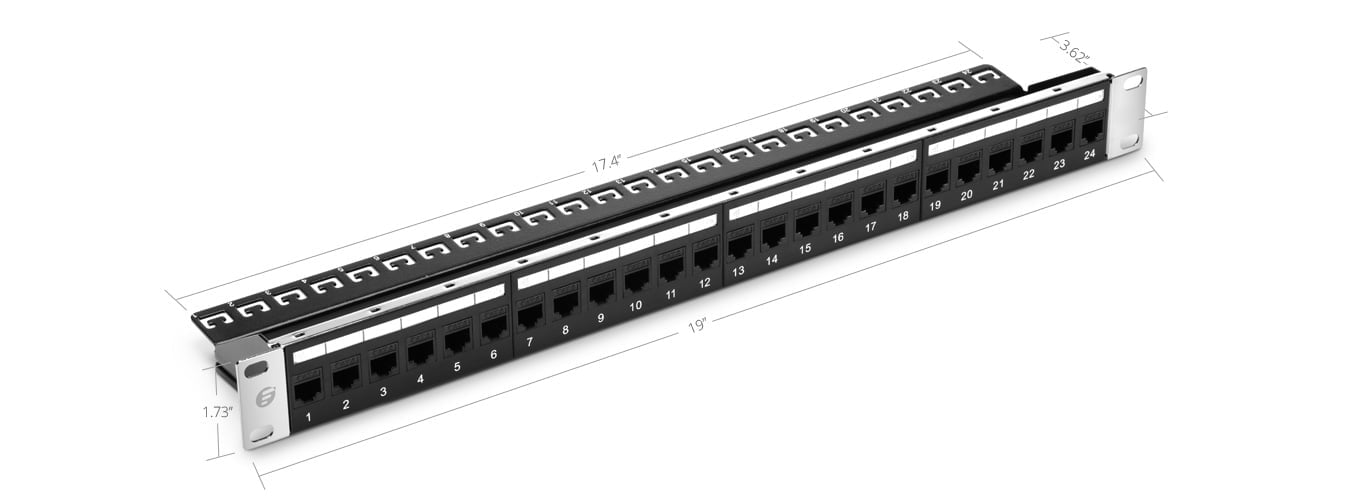

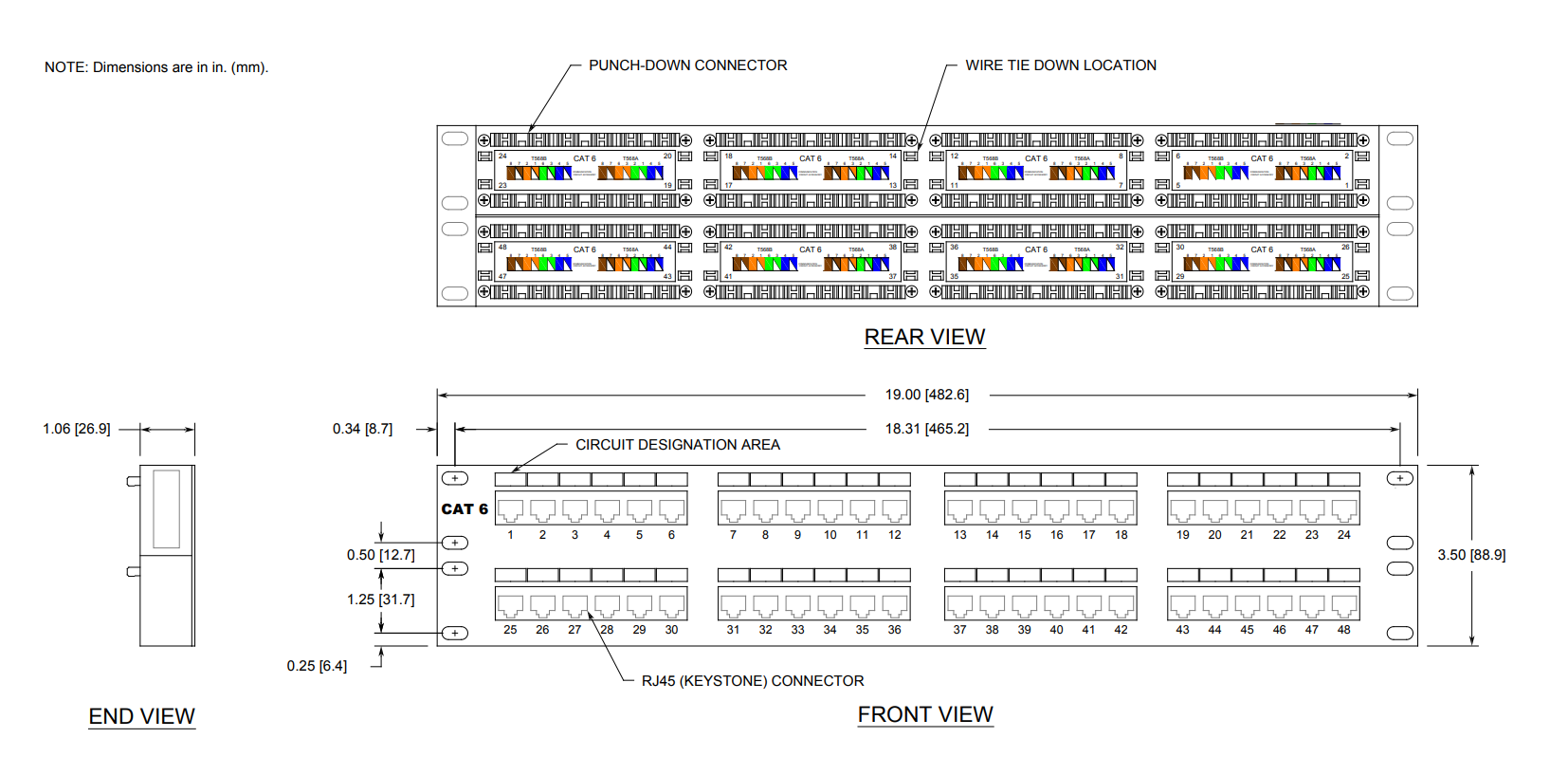

Ports are one of the most important of patch panel components, which are provided for data to enter and exit the panel. RJ45 patch panels typically consist of four or eight modules of eight ports each, for a total of 24 or 48 ports respectively. The 24-port patch panel is 1RU, the 32 and 48-port patch panel is 2RU, and the 96-port is 4RU. The following will show the detailed dimensions of 24-port patch panel and 48-port patch panel.

24-Port Patch Panel Dimensions

| Width | 19 in. (48.26 mm) |

| Height | 1.72 in. (43.68 mm) |

| Depth | 1.39 in. (35.30 mm) |

48-Port Patch Panel Dimensions

| Width | 19 in. (48.26 mm) |

| Height | 3.440 in. (87.38 mm) |

| Depth | 1.39 in. (35.30 mm) |

Designs of Copper Patch Panel

Shielded vs. Unshielded Patch Panel

Shielded and unshielded patch panels are required to match with the shielded and unshielded copper cable applications. Shielded patch panels are designed for high EMI (Electro Magnetic Interference) environments. These RJ45 patch panels can protect your high speed network from noise and EMI especially when the copper cables run near power cables. However, someone may wonder whether they can use unshielded patch panel for shielded cable. To be honest, it depends on the environment in which your cable will run through. If the place has no high power electrical wires, you can go with unshielded patch panel. On the flip side, if you are in a noisy environment like using arc welders or near high power radio transmitters, then you’d better select the shielded one. One more suggestion is that you may also consider the network speed. Both shielded and unshielded are suitable for 1G while only shielded is proper for 10G network.

Flat vs. Angled Patch Panel

Copper patch panels include flat and angled types from appearance design. Flat patch panel helps horizontal cable managers to organize and route cables into vertical managers. While angled patch panel is easy for cable termination and can improve patch cord routing. They serve as alternatives for management that need no rack space for horizontal management. The angled design increases rack density, managing high-density applications in one-fourth the area needed for conventional cable management systems. But angled patch panels are not good for cabinet installation due to the front depth requirements.

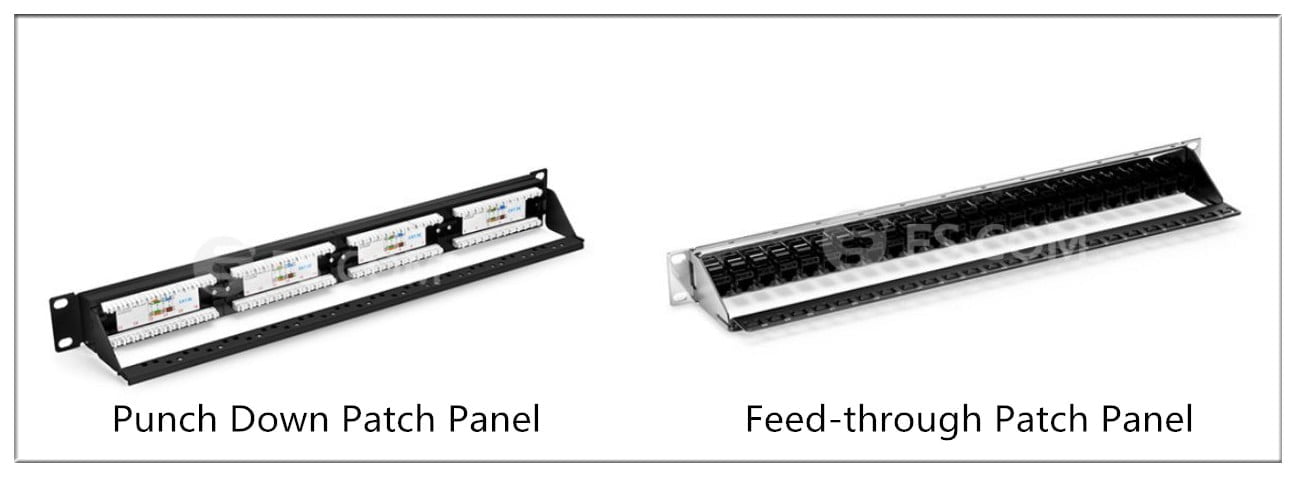

Punch Down vs. Feed-through Patch Panel

Punch down patch panel is a kind of network patch panel that should punch down Ethernet cable on the rear side. On the front plate, RJ45 ports can be directly connect Ethernet copper cable. However, feed-through patch panel provides patching without punching down the wires to the ports. Each feed-through patch panel has both RJ45 ports on the front and rear side. Nowadays, the feed-through patch panel is more acceptable than punch down patch panel in that the Ethernet patch cables can be inserted into the ports directly in an easy and fast way. For more information about punch down vs.

Common vs. High-Density Patch Panel

Common patch panels are always designed in 8 or 12-port configurations. While high-density patch panels are available in flat and angled designs with 24 or 48 ports configurations. High-density patch panel is suitable for installations with limited space. It’s a good choice for small home and office networks. High-density patch panel is specially designed for fast Ethernet applications and conserves rack space. So space is the first factor to be considered for making the decision between common and high density patch panels.

Copper Patch Panel Accessories

Copper patch panel accessories are basic components in Ethernet cable management, comprising of patch cables, jack modules, cable managers, cable ties and punch down tools to support full connectivity in LAN applications.

| Item | Description | Illustration |

|---|---|---|

| Cat5e Patch Cable | Multi-length and multiple jacket color of Cat5e patch cord available. | |

| Cat6 Patch Cable | Multi-length and multiple jacket color of Cat6 patch cord available. | |

| Punch Down Tool | Inserting wire into insulation-displacement connectors. | |

| Cable Ties | Multi-color magnetic cable tie | |

| Jack Modules | Multi-color shied/unshied Cat5e/Cat6 coupler keystone insert module | |

| Cable Manager & Wire Duct | 1U/2U horizontal cable manager with finger duct/brush strip/bend radius finger/D-rings/lacing bar, etc. |

Conclusion

Since there are so many types of copper patch panel in the market, choosing a suitable one is necessary for easy cable management. The above content has given a detailed introduction of several common types. Hope it can help you make a choice when you prepare to buy RJ45 patch panels.