Air Blowing Micro fiber Optic Cable system for underground duct networks. The Air Blowing Micro fiber Optic Cable product line is a complete solution with designs suitable for many applications and needs from backbone networks to FTTx. Whether the need is for high fiber density or small cable diameter, the Micro fIBER range has the solution. Designs are always based on minimal cable and duct diameters for cost effective installation and materials.

Micro fiber Optic Cable cables are jetted through a network of microducts using compressed air. Conduit systems can be laid and microducts and cable can be blown in as and when required. This gives installers the flexibility of deploying fiber only when needed, thereby reducing initial investment costs. Making provisions for future installations also means that only the very latest fiber optic technology is used and therefore scaled to changing market demands.

The Micro fiber Optic Cable system can be used for overriding existing networks and conduits, which reduces network disruption and expensive excavation costs and permits during installation. Micro fiber Optic Cable cable is lightweight and flexible made with a specially designed low friction jacket to enable greater jetting lengths to reduce time and cost.

Blown Optical Fiber technology provides flexibility in network design, while anticipating and facilitating future changes as the network evolves . It delivers the best fiber solution for backbone, specialty, Fiber-To-The-Desk (FTTD) and Fiber-To-The-Home (FTTH) applications

The cable can be used as the drop cable of distribution segments in FTTH networks and can be laid by air blowing to connect the branch point with the access point for subscribers. The cable is also applicable in backbone networks , metropolitan area networks and access networks

Air Blowing cable technology is a new way to make significant improvements in traditional fiber optic systems, facilitating the rapid adoption of fiber optic networks and providing users with a flexible, secure, cost-effective cabling system.

The blowing system consists of micro-tubes (single micro-tubes and micro-tubes), micro-cables, fittings and air blowing equipment.

The Air Blown Application

|  |  |

| Micro-tubes and Mother tube | Reducing Microduct Connector | Straight Microduct Connector |

The air blown fiber cable is composed of a combination of micro tubes (bundles), optical fibers (bundles), and blowing fiber devices.The air compressor is used as the power source for the traction fiber bundle, and the fiber bundle is quickly sent to the same micro tube bundle in the micro tube, and different types of fibers (beams) can be mixed and blown in different micro tubes.

To achieve fast installation and improved installation quality, all air-blown fiber cable are equipped with international standard prefabricated connectors on one end.

Technology & Features of Air Blowing Cable

Air Blowing Fiber Optical Cable Machine

- The Laying methods of Air Blowing cable compare with other Fiber Optical cable, the tension of the Air Blowing Cable during the laying process is relatively uniform and much smaller.

- The Air Blowing cable laying process is simplified and fast.

- The Air Blowing cable can lay a long distance in one time. It will reduce the number of joints and reduce the attenuation.

- The Air blown cable can greatly reduce the number of manholes and hand holes on the pipeline.

- There is less manpower used in blowing cable laying operations.

- It is convenient to replace the new type of optical fiber in the future, keep leading in technology and constantly adapt to market needs.

There are 3 types of HDPE Microduct Fiber Optic Cable for Blowing Use.HDPE multiple MicroDucts OR bundle MicroDucts is one or more micro ducts surrounded by a protective HDPE sheath.

1.Single core HDPE Microduct Fiber Optic Cable

Single core HDPE micro duct is the basic cell in the tube systmes, which is a high density polyethylene tube and diameter no bigger than Φ16.0mm. It is simple to be named as “as “the small size of the silicon core pipe.”” Within its materials solid silicon core wall with permanent lubrication, some specifications of micro-tube solid silicon core wall for vertical permanent lubrication layer, some specifications of micro-tube vertical guide rib tank, can further reduce the flow of the pipeline rib tank, can further reduce the friction of the inner walls of pipelines and cables to facilitate air laying fiber optic cable. Quoau offers a variety of micro-tubes are available for customers to choose, most often specifications including:Φ5/3.5mm,Φ7/3.5mm,Φ10/8mm,Φ12/9mm,Φ14/10mm and so on.

2. HDPE multiple MicroDucts

HDPE multiple MicroDucts combine the porous microtubes in a certain way, and the outer layer is covered with a polyethylene sheath to form a bundle, which achieves a greater number of tube holes in a limited space. The bundles of microtubules are independent of each other and facilitate the screening and continuation of microtubules. The outer sheath provides better mechanical strength to microtubules.

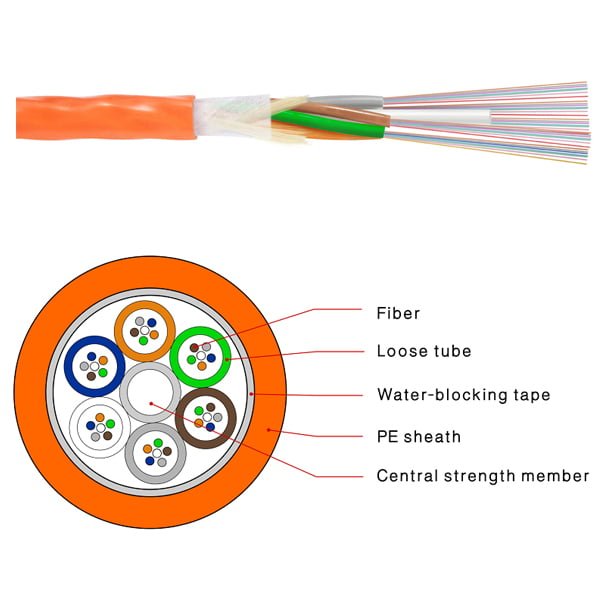

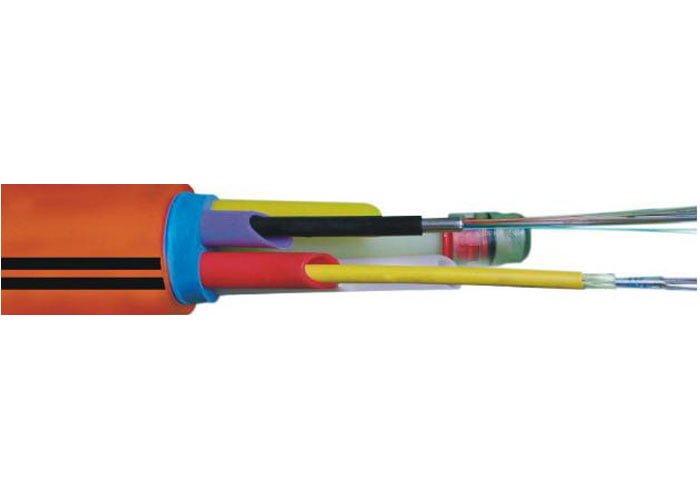

3.High performance air blown cable

High-performance air-blown cable for micro-piping system is still a common cable, but the same number of high-performance air-blown cable, the cable diameter is generally between 3.0mm ~ 10.5mm, large optical core can reach 288 core, with Small diameter, light weight, cable surface design form more in line with the characteristics of aerodynamics, but also referred to as micro-cable. As a result of the use of air blowing construction, blowing distance directly affect the cost of the project, so the cable is more suitable for air blowing method laying construction, can effectively improve the blowing distance, reduce the cost of the project.

For more reference, Please see the below image and you are welcome to contact us further.

Package:

Air Blowing Micro fiber Optic Cable

Hi,

Can we install direct buried steel armour FOC by air blowing technique? if No can you clarify why? and what if scenario if installed by air blowing, if there is any impact on the signal quality and attenuation after installation?

Thank you,

M Badawi

No, they are heavy and thick compare to Air blow cable