Fiber Optic Polishing Machine 550C Square Pressurized

$950.00

Fiber Optic Connector Polishing Machine Grinding Machine 550C Square Pressurized The high-performance polish machine offers superior quality and maximum capacity through put at a very affordable price. With high speed rotation & revolution method, this Square Pressure Fiber Optic Polishing Machine can polish 18~40 standard fiber optic connector at one time.

Fiber Optic Connector Polishing Machine Grinding Machine 550C Square Pressurized Fiber Optic Polishing Machine, Fiber Optic Polisher,

Fiber optic polishing machine is specially designed for ferrule polishing. The optional accessories – the various connector polishing jigs – allow the fixing and polishing of the most commonly used connector types. This polishing machine owns the advanced features as slow start, adjustable speed and weight, along with changeable polishing jigs.

A Fiber Optic Connector Polishing Machine is a specialized piece of equipment used in the fiber optic industry to polish the ends of fiber optic connectors. The polishing process is critical for ensuring that the connectors have a smooth, flat surface that allows for maximum light transmission between fibers.

The polishing machine typically consists of a motorized polishing plate or wheel that rotates at high speeds, along with specialized polishing pads or films that are used to achieve a precise level of finish on the connector end face. The polishing pads or films are typically made from materials such as diamond, aluminum oxide, or silicon carbide, which are selected based on the type of connector being polished and the desired finish.

To use the polishing machine, the fiber optic connector is first cleaned and inspected to ensure that there are no scratches or defects on the end face. The connector is then placed into a polishing fixture or holder, which positions it securely in front of the polishing pad or film. The polishing pad or film is then brought into contact with the connector end face and rotated at high speeds, while a small amount of polishing compound or slurry is applied to help remove any remaining imperfections.

The polishing process typically involves several stages of polishing, with progressively finer polishing pads or films used at each stage to achieve a smoother and more uniform finish. The final stage of polishing typically involves the use of a polishing film that has a very fine grit size, which produces a mirror-like finish on the connector end face.

Product Description:

The high-performance polish machine offers superior quality and maximum capacity through put at a very affordable price. With high speed rotation & revolution method, this Square Pressure Fiber Optic Polishing Machine can polish 18~40 standard fiber optic connector at one time. The square is pressurized by the spring, making the operation simple with high flexibility.typical Polishing Machine Adapt To Four Corners Compression And New I. P. C. Holder Technology Yields The Best Results In The Industry. No Variability In Result When Polishing 1 Or 24 Connectors, Jig Will Be Installed Stable, And Compact Size. This Fiber Optical Polishing Machine Can Process Excellent Connector End Force Polishing Quality. Our This Type Of Fiber Optical Polishing Machine Designed For Volume Production, High Productivity. For More, The Fiber Optical Polishing Machine Can Save Material And Low Cost For Polishing.

Product Highlights:

- May process each kind of standard fiber optic connectors, such as FC/UPC/APC,SC/UPC/APC, ST/UPC/APC, LC/UPC/APC, ,MU/UPC/APC, MTRJ,E2000/UPC/APC etc;

- Convenience for adjusting pressure, unloading and replacing jigs;

- Excellent connector and face polishing quality, the percentage of products sent back for repair is very low.

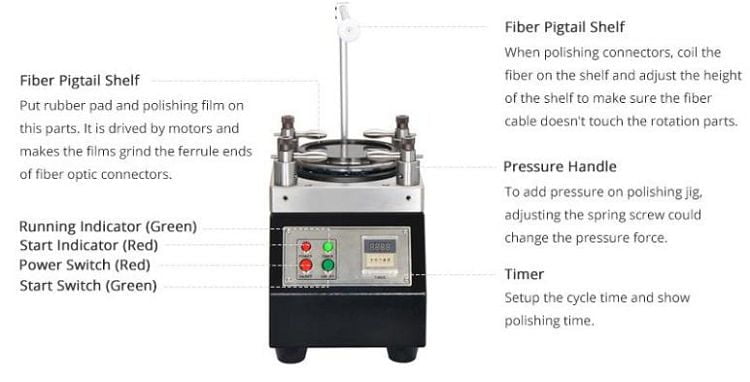

Frame Sketch:

The following Frame Sketch picture briefly introduce the main part of the polishing machine and their functions.

Ferrule material:

The industrial production qualified rate to be higher, and regardless of grinding 18 to 40 connectors, the polishing effect is the same with high operation flexibility and it can achieve fast polishing processes of each

kind of connectors with high effect.

● Packing Information:

● Packing Information:

| Pakage size | 41cm*40cm*33cm |

| Gross Weight | 28.2KG |

● Construction:

| Fiber count | Simplex (1-fiber) tight buffered Duplex (2-fiber) jacketed zipcord |

| Cable jacket ratings | Riser (OFNR) Low Smoke Zero Halogen (LSZH) per: IEC 60332-1-2, IEC 60332-3-24, IEC 60754-1, IEC 60754-2, IEC 61034-2 |

| Fiber types | Multi-mode: OM2 (G.651) 62.5/125um LWP Bend-Insensitive (G.651) |

| Connector types end ‘A’ | Simplex or Duplex LC/UPC, LC/UPC |

| Connector type end ‘B’ | Simplex or Duplex LC/UPC, LC/UPC |

| Jacket color | OM2 (G.651): Orange OM2 (G.651): Orange |

| Cable outside diameter (OD) | 1.6mm duplex and simplex 3mm duplex and simplex 900 micron tight buffered |

| Connector cable retention | 50N @ 0℃ 19.4N @ 90℃ |

| Connector durability | 500 cycles |

| Bend radius, minimum | 1.6mm: 16mm 3mm: 29mm 900 micron: 9mm |

● Fiber Parameter:

| Cable Material | |

| Outer sheath | LSZH (Aqua RAL 6027) |

| Outer sheath of single fiber | LSZH (Aqua RAL 6027) |

● Certification and Compliance:

| RoHS | Directive on Restriction of Hazardous Substances |

| GR-326-CORE | Generic Requirements for Single-mode Optical Connectors and Jumper Assemblies. Optical Fiber Cabling |

| TIA/EIA-568-C.3 | Components Standards |

| EIA/TIA-604 | Fiber Optic Connector Intermateability Standard |

| UL 94 | Our Third Party Tests for Flammability of Plastic Materials for Parts in Devices and appliances |

Overall, a Fiber Optic Connector Polishing Machine is an essential tool for anyone working in the fiber optic industry, as it allows for precise and repeatable polishing of fiber optic connectors, which is critical for ensuring maximum light transmission and optimal performance of fiber optic systems.

| Brand |

OEM |

|---|

Related products

FOCC

Your best partner For fiber optic products with 15 years of experience.Wholesale with competitive price and quality in China

Our Email:

Check our contact page

Our phone number:

+86-755 29360455

Our Address:

4th Floor, Building 1, YiJiaYang Science and Technology Park, No.159 HuaWang Road,Longhua District Shenzhen

Reviews

There are no reviews yet.