Polishing film 0.03μ ADS Patch Cord & Pigtails Production Line

$0.50

Polishing film 0.03μ ADS patch cord and pigtails Production Line The fiber optic polishing film also call fiber optic grinding we can supply the China fiber optic polishing film with low cost and also can supply Japan fiber optic polishing film with high quality.

Polishing film 0.03μ ADS patch cord and pigtails Production Line Polishing (Grinding) Machine

Polishing film 0.03μ ADS patch cord and pigtails Production Line The fiber optic polishing film also call fiber optic grinding we can supply the China fiber optic polishing film with low cost and also can supply Japan fiber optic polishing film with high quality.

Polishing film is a type of abrasive material used in the production of optical fibers, patch cords, and pigtails. The polishing film is typically made with a thin layer of abrasive particles coated onto a flexible substrate. The 0.03μ ADS refers to the size of the abrasive particles, which is 0.03 microns in diameter.

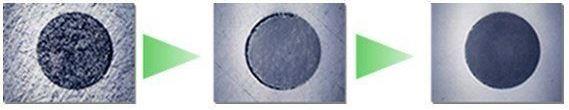

In a production line for patch cords and pigtails, polishing film is used to polish the end faces of optical fibers to ensure high-quality connections. The polishing process involves rubbing the end face of the fiber against the polishing film, which removes any imperfections and creates a smooth, flat surface. This ensures that the fibers can be connected with minimal loss of signal and minimal reflection.

Typically, a polishing machine is used in the production line to automate the polishing process and ensure consistent results. The machine uses a series of polishing films with progressively smaller abrasive particles to achieve the desir

Features

- The fiber optic polish film is the finally necessary item in fiber optic jumper wire grinding procedure

- It can minimize the scratch, there won’t be binding left on fiber surface after polished, and long service life, effectively save jumper cost

- The fiber optic polishing film is coated with precisely graded minerals (such as diamond, aluminum oxide, silicon carbide, silicon oxide, cerium oxide and so on) on the high strength polyester backing to provide a uniform, consistent finish

- Available in 0.01-45 μm grades, with or without PSA (Pressure Sensitive Adhesive) backing

- Perfect grinding efficiency for surface’s high-resolution with different precision demand

- Consistent finishing performance

- High durability and cost reduction

- Available for dry polishing and wet polishing.

Polishing Film Procedure in patch cord and pigtails Production Line

| Polish Step | Polish Film | Polish Fluid | Thrust (Std.) | Polish Time(Std.) | Polish Film Life |

| Adhesive removal (Hand Polish) | Abrasive paper | None | Approx 1 to 2kg | 15 sec | Disposed of every time |

| Grinding (1st Polish) | 9mic | Water | Point 2 | 50 sec | 30 times |

| Polish (2nd Polish) | 3mic | Water | Point 2 | 50 sec | 30 times |

| Polish (3rd Polish) | 1mic | Water | Point 3 | 50 sec | 30 times |

| Finish (4th Polish) | ADS (0.05mic) | Water | Point 3 | 40 sec | 10 times |

● Polishing effect:

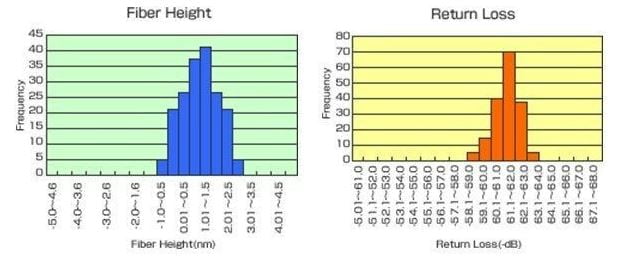

● Polishing effect:  ● Polishing Data:

● Polishing Data:

Wiki

Wiki

https://mefiberoptic.com/product/1%ce%bc-polishing-film-patch-cord-and-pigtails/

| HS Code |

6805200000 |

|---|---|

| Brand |

OEM |

Reviews

There are no reviews yet.