Tools & Equipment for Inspection, Tuning, Measurement and Cleaning

Tools & Accessories

Preparation & Polishing Tools

Inspection & Tuning

Measurement Equipment

Cleaning Tools

Fiber optic patch cords and Pigtails are very important passive fiber optic components in fiber optic networks. There are many different fiber optic patch cable types as per their connectors and cables in making a fiber optic patch cord. You can learn Fiber Optic Patch Cord Wiki first. You will know the basic knowledge about them. To a purchase manager or salesman, It is better to learn How to make Fiber Optic Patch Cord and Pigtail too.

Here below we are trying to give you General View about How to make Fiber Optic Patch Cord and Production Process.

General View about How to make Fiber Optic Patch Cord and Pigtail

There are often 10 necessary steps to make sure a fiber optic patch cord qualified globally in the market.

Step.1 Fiber Optic Patch Cord Cable Cutting

Before fiber patch cords making, we should prepare all the materials like fiber cable, fiber connectors etc. A patch cord cable is often in a reel and it should be cut by cutting machine as per the length requirements by customers,A fiber cable cutting machine makes it easy and effective in cabling cutting.

Step.2 Fiber Optic Patch Cable Cleaning & Pr-handling

Clean the cable after cutting is very important, This process is to make the fiber inside without any dust before inserting connector.Put the cable in good sequence so that it would be very easy to insert connector.

Step.3 Fiber Patch Jumper Cable Stripping & Identifying

Use the jacket stripper to strip the outer Jacket that may 3.0mm or 2.0mm or 0.9mm and use Fiber Miller Stripper Remove the Tight buffer Cladding of 0.9mm inner jacket of the Core and use the pastes to identify the cable for producing the duplex or multi patch cord.

Step.4 Fiber Optic Ferrule Glue Injection & Fiber Inserting

Inject some Epoxey Glue on the surface of the fiber and then inserting the fiber into the ferrule of connector. Usually it is professional glue called353 epoxy.You Can do it By hand or By machine .

Step.5 Fiber Patch cord Fiber Solidifying

Use vertical solidification furnace or horizontal solidification furnace to solidify the fiber on the connector.

Step.6 Fiber Patch Cable Ultrasonic Cleaning & Polishing

After solidifying, the half-finished patch cords need to be cleaned with ultrasonic cleaning machine.And the interface of the connector needs to be polished to make sure the fiber would be one the same line as the ferrule.

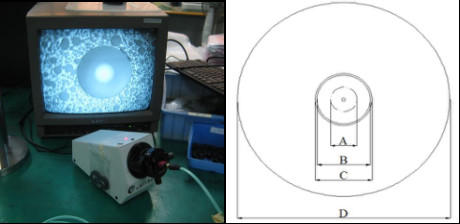

Step.7 Microscope Inspection for fiber jumper

Use 400 times or 600 times microscope to inspect the interface of the connector to make sure it clean. If there is any dust on the interface, we need to re-clean the connector again.

Step.8 FQC for a fiber patch cord

Use the inspection machines to do the FQC.It is important to test the patch cord for insertion and return loss value since they are the key factors affecting the function of patch cords.

Step.9 Kits Fast connector assembly to fiber optic patch cords

Assembly the other parts of connectors to the patch cords .

Step.10 Packaging a fiber patch cord

After all the testing, the patch cords would be packed according to customers’ needs.Usually, each patch cord would be packed in one bag in order to keep it safer.

After the above illustration, Do you have better understanding about How to make Fiber Optic Patch Cord? If not, Please feel free to contact us

It depend to number of worker(normally 4~5) and there speed and experiences and patch cord type .but it normal condition in 8 hours working day you could reach 500 pcs patch cords.

4 years, all the equipment test before delivery and until now we didn’t face any problem. If any things goes wrong we replace at the beginning, any way the tools are not high tech machine and expert mechanic can fix them quickly or replace them. Let me tell you your worker after while can open polishing machine for clearing and Lubrication even with close eyes…

We receive 500 USD a day for training + (Hotel min 3 Stare + Air thicket + Food base your local cost) but honestly you can learn the process by Films and on YouTube) and ask us any things during production to lead you. Or you can find local skillful worker from other factory in your place with lower cost, they will be happy to earn some money.

The machine consist of part for example polishing ,machine have motor part and PLC that are all high quality Items From Japan factory and assemble in our place and all the part have high standard that you can check .

If the worker use them properly and not hit in metal part it’s work for life time and plastic part as we use high quality ABS material min 500000 Time usable.

It depend to ferrule and the experience of worker but in generally for 24 jig 5 time and up 10 time. For pad you should change them after 500000 polishing time normally or some time earlier, your worker understand the time you need to change pad when they see the ferrule on microscope.

Dear most of the line are automated already (Cable cutting and polishing). there is another machine for stripe cable and buffer that i am not suggest, because you pay high money but this machine after while need maintenance and after some maintenance and calibration you need to change blade and after that machine cannot clear buffer and sometime worker need to trip by hand the remain and…. after some month worker prefer not to work with them because the buffer cutting by machine is not reliable. In brief expert and skillful worker for striping cable and buffer are more valuable and even speed raise after a while.

The Cable size is not matter . you can assemble connector to various cable 0.9/2.0/3.0/….. FTTA 7mm Cable , Drop Cable ….

whit this line you can not assemble MPO MTP connectors

I totally understand your concerns about the quality , But let me tell you that actually we don’t earn any profit by sealing you production line because we have to offer high quality products and our cost is higher compere to other , our main profit Continuous sales of raw materials for your product line and trail order for raw materials and consuming material , Because of that we only offer quality and reliable production line to our customer . Because if any inconvenience happen we lose your future orders.

How to make Fiber Optic Patch Cord and Pigtail Production Process

Hi,I have a plan for this fiber patchcord manufacturing..any one can guide me?please contact my watts app +0000000005.thanks.

I am interested in patch cord manufacturing. Please can I get you to assist?

Dear, we will send full information to your e-mail

Please, can you send it to me

Hi, i am interested to start patch chord manufacturing. could you please guide me with all the details

Dear , We will send you detail soon