FTTH DROP CABLE PRODUCTION LINE

$43,000.00

Optical cable production line makes FTTH drop fiber optic cable 2.0×3.0mm, 2.0×5.0mm. Cable structure: bare fibers + steel wires/FRP strengthen members + LSZH/PVC/PE sheath, and other similar cables.

FTTH DROP CABLE PRODUCTION LINE

Description

This Optical cable production line makes FTTH drop fiber optic cable 2.0×3.0mm, 2.0×5.0mm. Cable structure: bare fibers + steel wires/FRP strengthen members + LSZH/PVC/PE sheath, and other similar cables.

Features:

- 1, Precision special extruder and precision free adjustment head, the extruder is suitable for materials such as PVC, LSZH, PE and other materials.

- 2. The surface of the cable is smooth.

- 3. Optical fibers are motorized released. The tension is precisely constant and the additional loss is small.

- 4. The temperature control is controlled by imported OMRON temperature control meter, and the temperature control is accurate.

- 5, double-reels automatic take-up, stable and reliable operation, automatic line-receiving of the take-up line, no need to rewind.

- 6, International industrial computer technology control system with high degree of automation, it can be linked with MES, ERP systems, real time tracking and managing production.

- 7. The main control systems and components are international famous brands, and the production line has high stability and reliability.

FTTH drop cable production line

This production line is used for making FTTH cable. The line main components are:

Fiber pay-off, Strength member(FRP or Steel wire) payoff, Self suspending strength menber pay-off, Swing arm type dancer, Extrusion group 65mm, Cooling system, Cable dryer, Dual-axis diameter gauge, Ф600 wrap belt capstan, 70m Horizontal accumulator, Take-up and traversing unit, Electric control system

Butterfly-type drop optical cable is a new type of indoor fiber optic cable. It is suitable for indoor and terminal installation places that are often need to be bent. It can be cut according to the distance of the site when wiring, and it can be installed with quick connection connectors and optical fiber cold connectors. There is no need to melt fiber during site construction, which greatly improves engineering construction efficiency.

The structure of the butterfly-type drop optical cable is to place the optical fiber between two parallel reinforcements and then extrude a layer of plastic sheath.

The structure of the self-supporting butterfly-type optical fiber cable is to add a metal hanging wire to the structure of the common butterfly-type optical fiber cable. The structure is as follows:

The significant technical feature of the FTTH butterfly-introduced optical cable is not only to provide greater bandwidth, but also to enhance the network’s transparency of data formats, rates, wavelengths and protocols, relax requirements on environmental conditions and power supply, and simplify maintenance and installation. Therefore, this kind of optical cable has been widely used in optical communication systems and has good development prospects.

The introduction of FTTH butterfly cables requires special production equipment. Our company has many years of experience in research and development and manufacturing of optical fiber and cable production equipment. The FTTH butterfly-introduced optical cable production line provided is suitable for the production of (1-2) core butterfly-introduced optical cables. It can be extruded with PVC, LSZH and other jacket materials. The production line has the characteristics of uniform extrusion outer diameter, smooth appearance, fast production speed, high production efficiency, precise take-up and pay-off tension, and easy operation of the production line. It is a professional production equipment for FTTH butterfly-shaped optical cable.

The whole machine of the production line adopts the control technology combining industrial computer and programmable logic controller, namely (PC + PLC) method to realize the synchronous operation of the whole line and the independent operation of the single machine; the operation of the production line, the setting of the parameters and the display are all passed Industrial control computer to carry out, the production control process such as motor start, stop, signal given, motor speed and other production status acquisition are realized by PLC; data transmission between industrial control computer and PLC through communication port; production operation, alarm display can be realized , Emergency stop of production line and other functions.

Technical Parameters

- 1. Structure speed: 190m/min

- 2. Fiber tension: 0.4N-1.2N±0.05N

- 3. Additional loss: ≤0.02DB/KM (SM fiber)

- 4. Production line length: ≤26M

- 5. Power supply requirements: 63KVA, AC380V ±10% 50HZ three-phase five-wire

- 6. Normarl machine running power consumes: ≈35KW/h.

- 7. Production capacity: ≈9km/h( ftth cable 2.0X3.0mm), ≈7km/h( ftth cable 2.0X5.0mm),

Line Configuration

1. Φ800 Stengthen member bigger steel wire pay-off;

2. 4 heads fiber +2head FRP/ small Steel wire pay-off;

3. Mobile mold supporting;

4. 50 extruder;

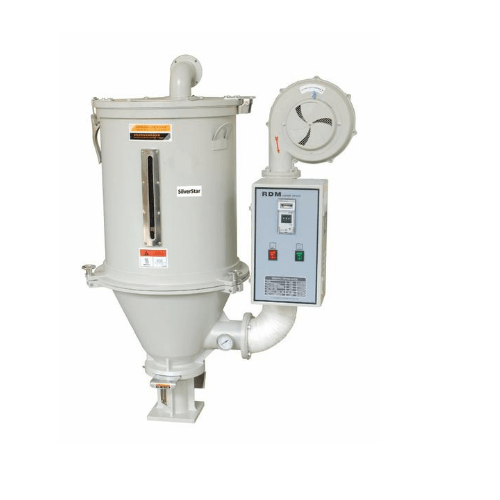

6. Dryer +hopper;

7. IPC+PLC program control systerm;

8. moving water trough and warm water tank;

9. fixed type cooling water trough and cooling water tank

10. laser diameter gauge;

11. dual-wheel capstan;

12. cable accumulator;

13. dual-wheel take-up

drop cable manufacturer, drop cable manufacturers, drop cable manufacturers in china, drop cable production, drop cable productions, ftth cable manufacturer, ftth cable manufacturers, ftth cable manufacturing, ftth cable product, ftth cable production, ftth cable productions, ftth cable products, Ftth Drop Cable Manufacturers, outdoor drop cable manufacturers, drop cable company ftth drop cable manufacturers

| Brand |

OEM |

|---|

Reviews

There are no reviews yet.