ADSS Fiber Optic Cable Production Line

ADSS Fiber Optic Cable Production Line , All-dielectric self-supporting (ADSS) cable is a type of optical fiber cable that is strong enough to support itself between structures without using conductive metal elements. It is used by electrical utility companies as a communications medium, installed along existing overhead transmission lines and often sharing the same support structures as the electrical conductors.

What Is ADSS Fiber Optic Cable Production Line?

ADSS Fiber Optic Cable Production Line , All-dielectric self-supporting (ADSS) cable is a type of optical fiber cable that is strong enough to support itself between structures without using conductive metal elements. It is used by electrical utility companies as a communications medium, installed along existing overhead transmission lines and often sharing the same support structures as the electrical conductors.ADSS Cables. All-Dielectric Self Supporting Cables. The All-Dielectric Self Supporting (ADSS) Cable Is A Completely Non-Metallic Structure In Which The Tensile Load-Bearing Elements Are Integral Within The Circular Design Of The Cable – Usually In The Form Of Aramid Yarns Or Stranded Glass-Reinforced Plastic Rods.

ADSS is an alternative to OPGW and OPAC with lower installation cost. The cables are designed to be strong enough to allow lengths of up to 700 metres to be installed between support towers. ADSS cable is designed to be lightweight and small in diameter to reduce the load on tower structures due to cable weight, wind, and ice.In the design of the cable, the internal glass optical fibers are supported with little or no strain, to maintain low optical loss throughout the life of the cable. The cable is jacketed to prevent moisture from degrading the fibers. The jacket also protects the polymer strength elements from the effect of solar ultraviolet light.Using single-mode fibers and light wavelengths of either 1310 or 1550 nanometres, circuits up to 100 km long are possible without repeaters. A single cable can carry as many as 864 fibers.

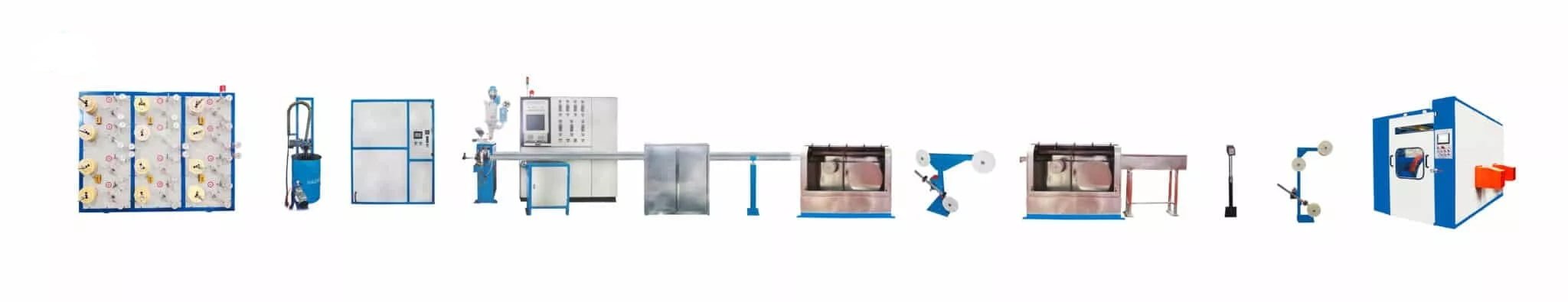

ADSS Fiber Optic Cable Production Line is consists of three main parts

1- IPC+PLC CONTROL LOOSE TUBE ADSS FIBER OPTIC PRODUCTION LINE

- 1-12 Heads Fiber Pay Off: Put On 1-12 Cores Fiber By Danfoss Driver.

- Jelly Filling Machine: Fill The Jelly Into The Loose Tube And Remove The Air From It By Automatic.

- Electrostatic Removal Device: Remove Impurities From The Fiber Surface Before Extruder.

- Masterbatch Compounder: Fill The Color Masterbatch Of Another Color.

- Dryer And Automatic Hopper Machine: Will Hopper And Dryer The Raw Material By Automatic.

- Main Extruder: Using The Best Quality Screw From China, Extrusion The PP/PPT Material. And The Motor Using Siemens.

- Control Cabinet: PLC+IPC Control, More Easy Operation For The Worker, The Transducer Using American Emerson, Other Electric Parts Using Schneider.

- Warm And Cooling Water Trough: Cooling The Wire Down Slowly.

- Diameter Gauge: Display The Actual Diameter Of The Cable To The Operator.

- Capstan: Automatic Change The Line Speed By Panasonic Servo.

- Semi-Automatic Take Up: Motor Using Siemens, Transducer Using Emerson, The Control System By 7-Inch Kincotouch Screen Puls Siemens S7-200 PLC Control. It Will Change The Wire Coil By Automatic When One Pcs Is Full.

2-SZ LOOSE TUBE BUNCHED ADSS FIBER OPTIC PRODUCTION LINE

As SZ stranding defines the mechanical and environmental properties of your loose tube fiber optic cable, you need technology that you can rely on. Our SZ stranding technology is not only reliable, but it helps you produce flexible and durable cable for use in various applications.

- Messenger Wire Pay Off: Put On The Messenger Wire

- Cylinder Dancer: Linkage With The Pay Off, Potentiometer + Cylinder Control

- Loose Tube Pay Off X 12 Sets: Put On The Loose Tube, The Max Cores Can Meet:12*12=144 Cores.

- Jelly Filling Machine: Fill The Jelly Before The Extruder Automatic.

- Dryer And Automatic Hopper Machine: Will Hopper And Dryer The Raw Material By Automatic.

- Control Cabinet: PLC+IPC Control, More Easy Operation For The Worker, The Transducer Using American Emerson, Other Electric Parts Using Schneider.

- SZ Stranding Device: The Control By Servo Motor And The Angle Can Be Adjustments From ±4π Unit ±20π.

- Double Heads Cross-Binder Machine: Cross Binding The Loose Tube By Servo Motor Plus Emerson Control.

- Single Head Cross-Binder Machine: Cores Binding The Loose Tube By Servo Motor Plus Emerson Control.

- Double Heads Wrapping Machine: Put On The Water Blocking Tape/Aluminum Foil/PET Film Etc.

- Diameter Gauge: Display The Actual Diameter Of The Cable To The Operator.

- 800mm Wheel Flat Belt Capstan Machine: The Power By Siemens Motor Plus Deceleration Box Plus Emersoncontrol.

- Cylinder Dancer: Linkage With The Take Up, Potentiometer + Cylinder Control

- 800-1600mm Gantry Type Take Up: Motor: Siemens, Drive: Emerson, Touch Screen: Siemens, PLC System: Siemens S7-1200

3-OPTICAL CABLE SHEATHING ADSS FIBER OPTIC PRODUCTION LINE

The sheathing process is where you apply the final touch to your loose tube fiber optic cable. Mechanical properties for different cable types are set with armoring and strength members. Our state-of-the-art extrusion technology offers you the ability to utilize a large variety of plastic materials to produce high-quality jacketing.

The sheathing normally contains the following components by option: Pay-off with tension dancer, yarn server, Steel tape pay-off, Jib crane, Steel tape Splice table & Welder, Metal tape accumulator, Steel tape corrugation and lubricator, Ripcord pay-off, Steel tape cone forming station, Armor powder application system for cone forming, Water blocking tape pay-off, Dual single head concentric binder, Mylar tape pay-off , Hot melt applicator,.90mm(or 120mm) Extrude, First Water trough, Second water trough, Diameter gauge/ lump detector, Spark tester, Hot stamp printer, Linear Belt Capstan, Cable accumulator, Take-up, Electrical control system (PLC)

- 800-1600mm Gantry Type Pay Off: Motor: Siemens, Drive: Emerson, Touch Screen: Siemens, PLC System: Siemens S7-1200

- Cylinder Dancer: Linkage With The Pay Off, Potentiometer + Cylinder Control

- Messenger Wire Pay Off-1 Set: Put On The Messenger Wire.

- Armind Yarn Stranding Device* 2: 24-Heads Magnetic Damping Control

- Double Heads Steel Aluminum Tape Pay Off: Put On Steel-Aluminum.

- On-Line Seam Welding Device: Joint Weld Steel& Aluminum Tape When Changing One Tape Drum To Another.

- Metal Tape Corrugating Device: Corrugated The Steel Aluminum Before Extruder.

- Metal Tape Longitudinal Forming Device: Longitudinal Forming And Fixed Diameter Before The Extruder

- Aramid Yarn Pay Off: Twist The Aramid Yarn With The Loose Tube After Aluminum. The Tension Control By Each’ Magnetic Damping.

- Dryer And Automatic Hopper Machine: Will Hopper And Dryer The Raw Material By Automatic.

- Main Extruder: Using The Best Quality Screw From China, Extrusion The PE/PVC Material. And The Motor Using Siemens.

- Control Cabinet: PLC+IPC Control, More Easy Operation For The Worker, The Transducer Using American Emerson, Other Electric Parts Using Schneider.

- Warm And Cooling Water Trough: Cooling The Wire Down Slowly.

- Diameter Gauge: Display The Actual Diameter Of The Cable To The Operator.

- Capstan:Power: 7.5KW Siemensmotor + Deceleration Box + 7.5KW American Emersontransducer + Speed-Governor.

- Power Frequency Spark Machine: Online Test For Outer Sheathing Breakage.

- Cylinder Dancer: Linkage With The Take Up, Potentiometer + Cylinder Control

- 800-1600mm Gantry Type Take Up: Motor: Siemens, Drive: Emerson, Touch Screen: Siemens, PLC System: Siemens S7-1200

What Is ADSS Cable?

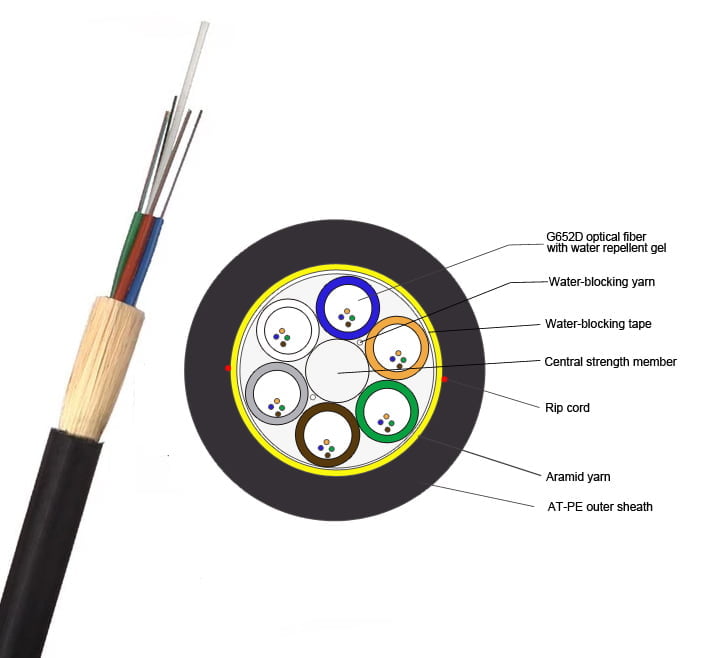

ADSS cable is a type of fiber optic cable that is strong enough to support itself between structures without containing conductive metal elements. Both single mode and multimode fibers can be arranged in ADSS cables with a maximum of 144 fibers. ADSS fiber optic cable is designed for outside plant aerial and duct applications in local and campus network loop architectures from pole-to-building to town-to-town installations. The cabling system that includes cables, suspension, dead-end, and termination enclosures offers a comprehensive transmission circuit infrastructure with high-reliability performance.

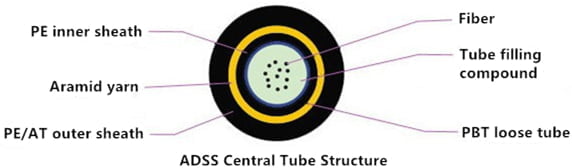

The structure of ADSS cable can be divided into two categories—central tube structure and stranded structure. In a central tube design, the fibers are placed in a PBT loose tube filled with water-blocking material within a certain length. Then they are wrapped with aramid yarn according to the desired tensile strength and extruded with PE (≤110KV electric field strength) or AT (≥100KV electric field strength) sheath. This structure features with small diameter and light weight but has limited lengths.

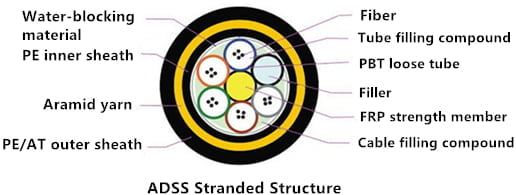

In a stranded structure design, the inner optical fibers and water-blocking grease are added into the fiber loose tube, and different loose tubes are wound around the central reinforcement (usually FRP). The rest parts are basically similar to the central tube structure. This type is able to obtain longer fiber lengths. Although the diameter and weight are relatively big, ADSS cables with this structure are better to be deployed for large span applications.

What Are the Benefits of ADSS Cables?

When it comes to aerial cablings or outside plant (OSP) deployments, ADSS cable will provide an efficient and optimal solution in most of the cases. The remarkable advantages of this ADSS fiber cable are twofold: reliable and cost-effective.

Fundamentally speaking, ADSS fiber optic cable is small in size, light in weight, strong in structure, and flexible in applications, which is suitable for most outside aerial deployments. The small and light nature of the ADSS cable will reduce the load on tower structures for some external influencing factors like cable weight, wind, ice, etc. The structure design will not only prevent moisture and chemical attacks but also will protect the polymer strength elements from the effect of solar ultraviolet light. Besides, the strong structure will also allow up to 700m lengths to be installed between support towers.

Economically speaking, as an alternative to OPGW (Optical Fiber Ground Wire) and OPAC (Optical Attached Cable) solutions, ADSS cable can provide a cost-effective solution by saving the money and the resources with easier installment and wider ranges. Adopting ADSS cables can exploit the considerable economic advantages offered by the installation of existing high voltage power lines. In addition, the installation of ADSS cables is faster and easier than previous aerial designs. Do not need support or messenger wires, a single pass is sufficient for installation. ADSS cable can be used for applications ranging from short span (40-50 meter) distribution lines to long-span transmission lines (300-500 meter spans) to extraordinary spans required by some river canyon crossings exceeding 1,800 meters.

What Are the Applications of ADSS Cables?

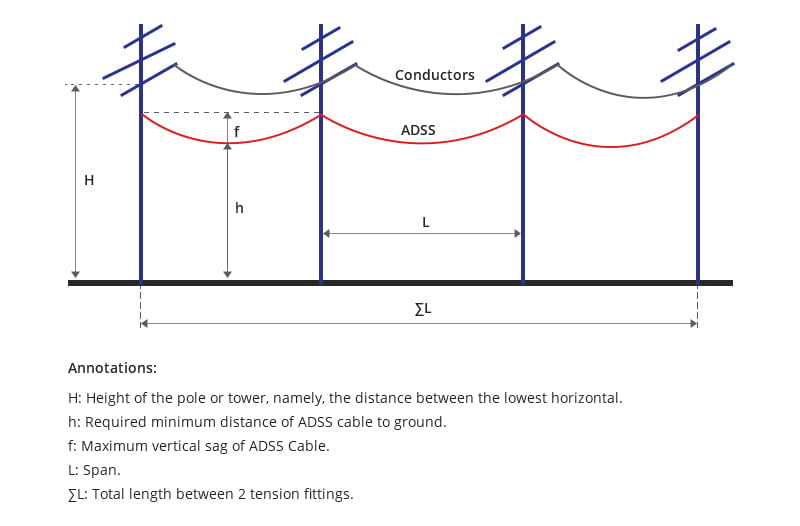

Originally, ADSS cable was developed from a military lightweight rugged deployable (LRD) field cable. With the continuous improvements, it is now used for short span aerial installations—typically on roadside power distribution poles. Since the ADSS cable is non-metallic, it is ideal for applications near high-voltage power distribution lines for which it has become a standard. Using single mode fibers and light wavelengths of either 1310 nm or 1550 nm, circuits up to 100 km long are possible without repeaters. Usually, ADSS was used in 48 and 96 cores. Here is a sketch of a normal ADSS cabling scenario:

In addition, ADSS fiber cable is also suited to single-point suspension applications such as down mine shafts or any application where the product has to support either a higher load than conventional terrestrial cable or a permanent or varying tensile load that is applied through the outer sheath. What’s more, ADSS can withstand the worst-case combinations of extreme weather, ice load, and wind environments, guaranteeing reliable communications in outdoor situations.

Conclusion

ADSS cable is ideal for installation in distribution as well as transmission environments. Since the ADSS cables provide an optimal solution for a broader combination of fiber counts and span lengths, more and more aerial cabling system designers tend to adopt them for telecommunications, like power utilities, telcos, and private network groups. Combining convenience and cost-effectiveness, an aerial fiber-optic deployment requires this kind of fiber optic cables for better performance.

https://mefiberoptic.com/what-is-adss-fiber-optic-cable/

Reviews

There are no reviews yet.