MicroDucts (Air Pipe) and Duct in FTTx Network

MicroDucts and Duct are used for FTTx network extensions.The product range is consists of

- Microducts (DB/DI)

- Flat Duct

- Flat Flex Duct

- Indoor Microducts(Plenum Microduct)

- Figure 8 Microducts (Aerial Microduct)

- Hybrid Microducts

- Duct(Silicone Coated HDPE Ducts)

MicroDucts

HDPE Microducts are suitable for use in network applications such as FTTH (Fibre to the Home), FttB (Fibre to the Building), FttC (Fibre to the Curb) or the last mile.Microducts are designed for long term protection of fiber optical cables and are especially suitable for installation of micro cables.Direct Bury type of microducts are thick wall products that attain their mechanical robustness and functional performance through their intrinsic thick walls and need no further protection in underground installations.

Single-hole microtube are the most basic components of the micro-piping system. They are high-density polyethylene (HDPE) as the main raw material, the plastic pipe with the nominal diameter of not more than 22mm can be understood as the smaller size silicon core tube. The inner wall of the pipe also has a continuous production of extruded permanent solid silicon core lubrication layer, part of the specifications of the micro tube wall with a longitudinal guide rib structure, further reducing the friction coefficient of the inner wall of the pipeline to facilitate the laying of fiber optic cable.

They have a size ranging from typically 3 to 22 mm and are installed as bundles in larger ducts. different sizes and configurations of Microducts for a variety of applications, such as: Backbone, Back-haul, Direct Buried, Directional Drilling, Over-Rides and populating existing conduits. In order to get the best product performance, please contact Us for more information.

Direct Buried Microducts (DB)

Direct Bury type of microducts are thick wall products that attain their mechanical robustness and functional performance through their intrinsic thick walls and need no further protection in underground installations.In Direct Buried (DB) applications, the Microducts will be directly buried, or bundled into Bundle configurations. Using a thicker walled Microduct is recommended to maintain the optimum fill ratios and have faster, easier installations.

Direct Install (DI)

Direct Install (DI) In applications where the Microduct or Microduct Multi configuration will be placed inside an existing conduit, like an Over-Ride or populating and existing conduit, we recommend using a thinner walled product where protection is provided by the existing conduit and space is more sensitive.

Thick and thin walled microducts Different in size and applications.

Thick walled microducts: have a solid wall thickness that is robust enough to protect the optical fibers running inside of them. Typical dimensions for the thick walled microducts (OD/ID) are 7/3.5mm, 8/4.4mm, 8/3.3mm, 10/6mm, 12/8mm, 14/10mm, 16/12mm, 16/10mm, 20/16mm, and 25/21mm …designed for long term protection of fiber optical cables and are especially suitable for installation of micro cables. Direct Bury type of microducts are thick wall products that attain their mechanical robustness and functional performance through their intrinsic thick walls and need no further protection in underground installations.

Thick walled microducts 7/3.5mm

Microducts bundled into one package up to 1/2/3/4/5/6/7/12/14/19/24 Way

Thick walled microducts 10/6mm

Microducts bundled into one package up to 1/2/3/4/5/6/7/12 Way

Thick walled microducts 12/8mm

Microducts bundled into one package up to 1/2/3/4/5/6/7 Way

Thick walled microducts 14/10mm

Microducts bundled into one package up to 1/2/3/4/5/6/7 Way

Thick walled microducts 16/12mm

Microducts bundled into one package up to 1/2/3/4/5/6/7 Way

Thin walled microducts: have lower wall thickness. Usually they are augmented with one or more outer layers of protection that makes these ducts robust enough for the application. Typical dimensions of the thin walled micro tubes are (OD/ID) 3/2mm, 5/3.5mm, 7/5.5mm, 10/8mm, 12/10mm, 14/12mm , …usually used in existing Duct/Pipe or Sub-Ducts Direct Install (DI) to maximize the utilization of already existing infrastructure.

Thin walled microducts 5/3.5mm

Microducts bundled into one package up to 1/2/3/4/5/6/7/12 Way

Thin walled microducts 10/8mm

Microducts bundled into one package up to 1/2/3/4/5/6/7 Way

Thin walled microducts 12/10mm

Microducts bundled into one package up to 1/2/3/4/5/6/7 Way

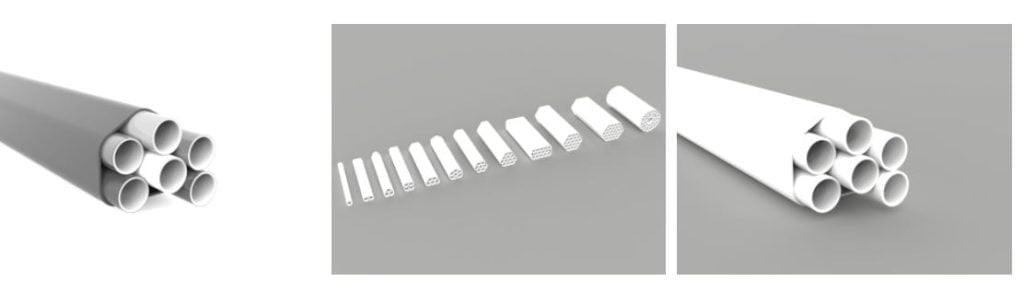

Bundled microduct

Microducts use in bundled into one package by over-sheathing them with a Polyethylene jacket is a configuration of 2 way , 3 way , 4 way , 6 way , 7 way, 8 way, 12 way, 19 or 24 way MicroDucts, factory base on size of single microducts size.

HDPE Microduct Benefits

Best Performance

HDPE Microduct cables exhibit no loss in performance over time or in extreme temperature conditions.

Increased Efficiency In Network Building

- possibility of using ducts of different color allows to distinguish cables when several cables are installed in a single trench.

- a print indicating length of cables gives information about the length of the cable installed.

- ease of connecting the ducts with the aid of couplings.

Better Cable Protection

By using high density polyethylene (HDPE) for mechanical protection of fiber optic and metal cables, and surrounded by a layer of moisture-barrier metallic or non-metallic tape, HDPE Microduct provides a protection for the installed cables.

Quick, Simple, Time And Cost Saving Branching

They permit an easy replacement of cables without the necessity to dig the cables out, mostly designated for more effective FTTH deployment.

Compatible With Actual Installation Methods

HDPE Microduct cables can be easily installed using standard ISP/OSP installation methods in common applications.

High Environmental Resistance

- High crush resistance, as the strength imparting the duct compression resistance.

- Heat resistance providing satisfactory mechanical properties in the temperature range from -20 to +55 °C.

- resistance to moisture, oil, petrol, rodents, and other unfavorable factors that may affect the duct underground.

Features

- Outer Diameter 4 to 22 mm, Versions DI and DB

- Supplied as single tubes or bundle configurations

- Made from High Density Polyethylene (HDPE)

- Silicone inner lining to reduce friction on cable blowing

- Excellent stress crack and stress crush resistance

- Highly resistant to crushing and external impacts

- Suitable for all environments (green or brown fields)

- Optional ribbed surface that enables cable blowing

- Reduced coefficient of friction

- Future proof, can accommodate more cables

- Cost-effective repairs of upgrades

- Requires less connections

Advantages of Microduct over Traditional Methods

- Microduct products are easily and quickly intalled in direct buried applications using minimally invasive micro-trenching equipment.

- Microduct pathways offer superior mechanical and enviromental protection for lightweight microfiber optical cables, which can be easily installed using various air blowing techniques, or traditional cable pulling / pushing methods.

- Microduct patway systems offer telecom carriers increased flexibility de to the ease at which service laterals and drops can be reconfigured and installed as customer demand increases.

Optional

- Silicone Inner Lining

- Custom Marking

- Smooth or Ribbed Wall

- Trace wire for location detection

Flat MicroDuct

Flat microduct bundles are a more recent development. The flat configuration is resistant to twisting, which enables smoother installation.For micro-trenching with narrow width, Flat Duct is the most compatible item. The product can be placed vertically to fit on micro-trenching dimension.The size of product is relatively tiny which allows better shipping and handling with smaller reel size. As Flat Duct has the same thickness of Bundle Microduct, customers can enjoy the same benefits of Bundle Microduct.Easy to branch-off. For a blown fiber or multiduct system you need expensive tools for branch-offs.

Flat Flex Duct

Indoor Microducts(LSZH/Plenum Microduct)

LSZH/Plenum Microduct is a durable, polyvinylidene difluoride (PVDF) crush resistant microduct suitable for protecting fiber in any indoor application. Easily mated with an airtight and waterproof coupler, FieldShield Plenum Microducts integrate with direct bury and aerial microducts creating a single and continuous pathway from outside plant to inside plant environments.

LSZH or Plenum Indoor Microduct Products are the most appropriate for in-building infrastructure.

Figure 8 Microducts (Aerial Microduct)

figure-8, self supporting aerial configurations. Options are for 12.7/10mm and 18/14mm designs, and they offer multiple pathways in a single aerial attachment.

No over lashing required, and additional cables can be blown in easily. Transitions from aerial to underground are possible with no splices required.

Hybrid Microducts

hybrid allows for lower cost pathway deployments in dense areas where higher fiber counts are needed.

hello dear

im reza from iran.

i have decided to buy a microduct bundle pipe extrusion line.how can you help me?

can you introduce me to some companies in this field?

thanks alot

Nice article Tom