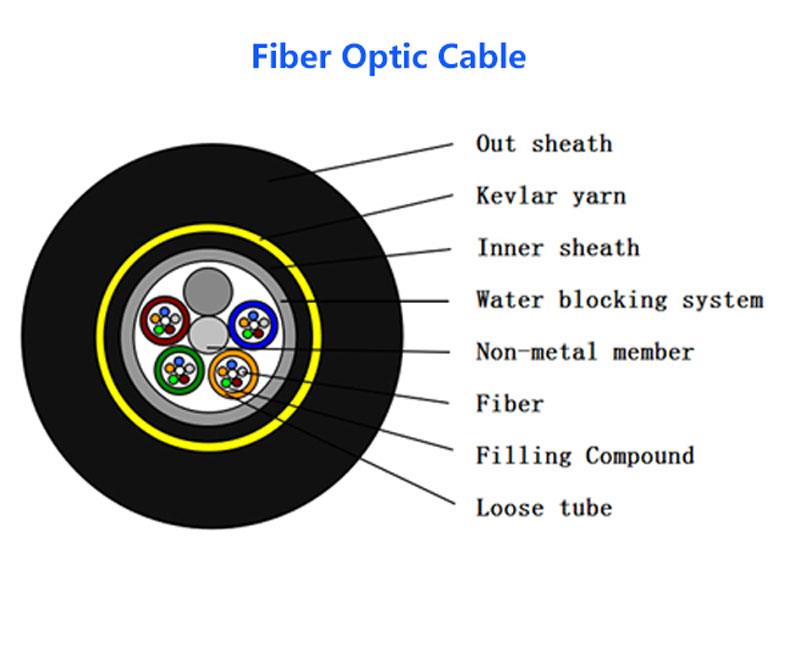

ADSS cable is loose tube stranded. Fibers, 250µm, are positioned into a loose tube made of high modulus plastics. The tubes are filled with a water-resistant filling compound. The tubes (and fillers) are stranded around a FRP (Fiber Reinforced Plastic) as a non-metallic central strength member into a compact and circular cable core. After the cable core is filled with filling compound, it is covered with thin PE (polyethylene) inner sheath. After stranded layer of aramid yarns are applied over the inner sheath as strength member, the cable is completed with PE or AT (anti-tracking) outer sheath.

ADSS Aerial Cable is designed to be freely suspended between upright supports such as poles, posts and masts. The construction is waterproof in longitudinal direction thanks to the use of jelly-filled bundle conductors and swelling tape. The outer jacket is UV-resistant and at the same time provides protection against environmental influences such as snow, ice, sun isolation and wind. The loose tube design provides stable performance over a wide temperature range and is compatible with any telecommunications-grade optical fibre. ADSS is available in various span lengths and wind loads.

ADSS cable can be installed using live-line methods on an energized transmission line. Fiber cables are generally supported on the lower cross-arms of the tower, which provides good clearance to the ground. When the fibers are installed in the middle of a tower, the fiber cable is unlikely to hit energized conductors. Lower weights and forces are used for installation, compared with metallic cables, so lighter equipment can be used.

Installation technique is similar to installing overhead conductors, with care taken to prevent excessively tight bending of the cable, and adjustment of the sag of individual spans as for metallic cables.

Feature / Benefit

•Up to 96 fibers (AD10), Up to 144 fibers (AD20)

•High resistance to tracking effect provides long operating lifetime

•SZ stranding design allows for easy mid-span access and isolates

fibers from installation and environmental rigors

•Drycore design for excellent water blocking performance

and easier handling

•Minimized additional loads due to small diameter and lightweight

with the high strength aramid yarns

•Custom designs available *

•Complies with IEEE P-1222, the recognized standard for ADSS fiber optic cable

* Note: The sheath material (MDPE or TRPE) and the location of the cable on structures that support

110KV or higher circuits should be reviewed prior to installation.