12 Core MPO MTP TO LC Harnesses Cables SM OS2

12 Core MPO MTP TO LC Harnesses Cables SM OS2 are used to fan out the XX core MPO/MTP fibers into generic connectors, usually it is MPO/MTP to LC, but we can also make it MPO/MTP to SC/ST, FC, MTRJ, E2000, etc. The MPO/MTP harness cable is used to transit from backbone trunk cables to fiber management racks, cable jackets available are Mini-Core Plenum (OFNP), Mini-Core Riser (OFNR), Mini-Core Low Smoke Zero Halogen (LSZH), typical optical fiber types are single mode OS2, multimode OM1, OM2, OM3, OM4, OM5. The MPO/MTP to LC harness cables can be made with 2mm or 3mm ruggedized furcation legs in customized length, this will hep make it more rugged.

MPO MTP Multi-fiber push on connectors, or MPOs for short, are fiber connectors comprised of multiple optical fibers. While defined as an array connector having more than 2 fibers, MPO Connectors are typically available with 8, 12 or 24 fibers for common data center and LAN applications.

LC Connector (Lucent Connector) A miniaturized version of the fiber-optic SC connector. It looks somewhat like the SC, but is half the size with a 1.25mm ferrule instead of 2.5mm. See SC connector. LC and SC Connectors. LC and SC optical connectors use a push-pull plug similar to audio and video plugs and sockets.

Cable assemblies are a group of cables or wires that are wrapped in an outer layer of a different product to keep the cables together. The purpose of cable assemblies is to keep wires and cables organized. These cable assemblies usually serve a similar function to wire harnesses, but are designed for completely different environments. Most of the time, they are made from heavy-duty materials like vinyl, thermoplastic rubber, or shrink-wrapped thermoplastic

Wire harnesses are more of a basic exterior coating that covers the smaller wires and cables inside. The purpose of wire harnesses is to bundle up cables and wires that are already protected by an outer layer. This essentially means that if you were to open a wire harness, you would see numerous cables with their own covers as opposed to one single wire. Wire harness manufacturers have been making wire harnesses out of thermoplastic and thermoset material for years. These materials will help protect the wires from environmental conditions.

Application 12 Core MPO MTP TO LC Harnesses Cables SM OS2

- Data communication network.

- Optical System Access network.

- Storage area networking fiber channel.

- High density architectures.

Features

- 100% pre-terminated and tested in factory to ensure transfer performance.

- Rapid configuration and networking, reduce installation time.

- Supports 40G and 100G network

- Cable Jacket material: LSZH, OFNR, OFNP

- Supports up to 12F, 24F, 48F, 72F, 96F, 144F, customized products are

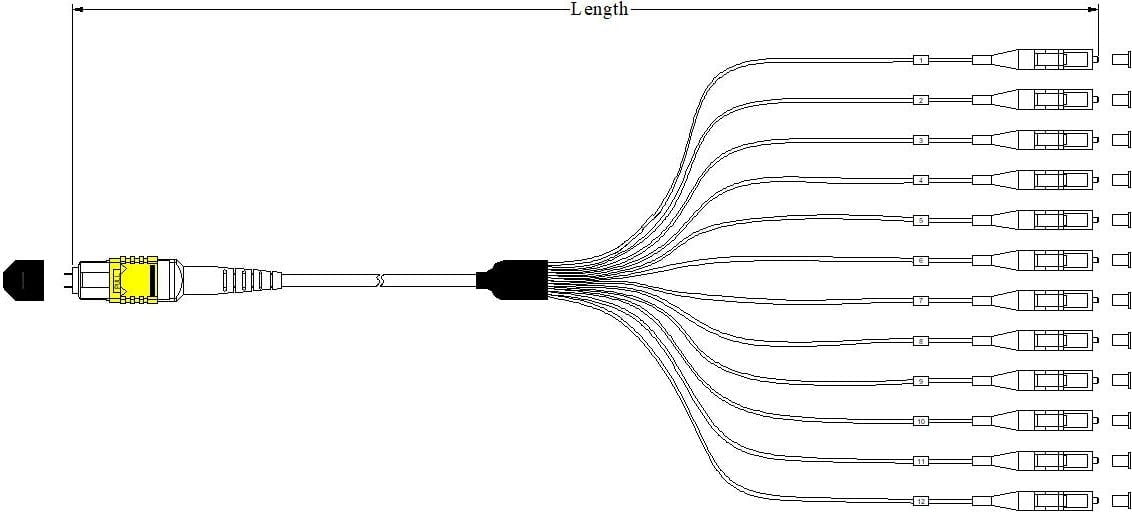

Dimensional Diagrams

- MPO/MTP Harnesses Cables

Patch cord versions

| Jumper tolerance requirement | |

| Overall length (L) (M) | length of tolerance(CM) |

| 0<L≤20 | +10/-0 |

| 20<L≤40 | +15/-0 |

| L>40 | +0.5%L/-0 |

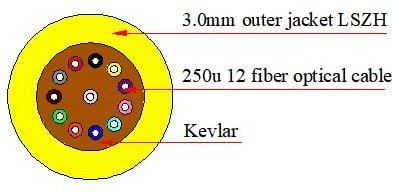

Cable Structure

Cable Parameters

|

Fiber account |

OD(mm) |

Nominal Weight (kg/km) |

Max.tensile Strength(N) |

Max.Crush Resistance (N/100mm) |

Min.Bending Radius(mm) | |||

| Short-term | Long-term | Short-term | Long-term | Dynamic | Static | |||

| 12 | 3.0±0.15 | 7.0 | 180 | 90 | 500 | 150 | 20D | 10D |

MPO&MTP Optical Characteristics

|

Item |

Parameter |

Reference |

|||

| Single mode | Multimode | ||||

| Standard | Elite | Standard | Elite | ||

| Insertion loss | Typical≤0.30dB

Max≤0.75dB |

Typical≤0.15dB

Max≤0.35dB |

Typical≤0.50dB

Max≤0.25dB |

Typical≤0.10dB

Max≤0.35dB |

IEC 61300-3-34 |

| Return loss | ≥ 50dB (PC)

≥ 60dB (APC) |

≥ 55dB (PC)

≥ 65dB (APC) |

≥30dB(PC) | ≥30dB(PC) | IEC 61300-3-6 |

LC/SC/FC/ST Optical Characteristics

|

Item |

Parameter |

Reference |

|

| Single mode | Multimode | ||

| Insertion loss | Typical value≤0.15dB;Maximum≤0.30 | Typical value≤0.15dB;Maximum≤0.30 | IEC 61300-3-34 |

| Return loss | ≥ 60dB (APC);

≥ 50dB (UPC) |

≥30dB (UPC) | IEC 61300-3-6 |

End-Face Geometry

| Item | UPC (Ref: IEC 61755-3-1) | APC (Ref: IEC 61755-3-2) |

| Radius of curvature (mm) | 10 to 25 | 5 to 12 |

| Fiber height (nm) | -100 to 100 | -100 to 100 |

| Apex offset (μm) | 0 to 50 | 0 to 50 |

| APC angle (°) | / | 8° ±0.2° |

| Key error (°) | / | 0.2° max |

End-Face Geometry

|

Ferrule parameter |

IEC-61300–3-30 | |||

| Minimum | Maximum | |||

|

ROC |

ROC-X: | 2000mm | ∞ | |

| ROC-Y: | 50mm | ∞ | ||

|

Angle |

Angle-X: | -0.2° | 0.2° | |

|

Angle-Y: |

PC | -0.2° | 0.2° | |

| APC | 7.85° | 8.15° | ||

| Fiber Hight: | 1000nm | 3500nm | ||

| Max.DH.All: | -300nm | 300nm | ||

| DH.Adj: | -300nm | 300nm | ||

| DH.Ave Fiber: | -300nm | 300nm | ||

|

Core Dip: |

MM | -200nm | 300nm | |

| SM | N/A | N/A | ||

| Ferrule height | 7.9mm | 8.05mm | ||

End-Face Qualty (SM)

| Zone | Range (μm) | Scratches | Defects | Reference |

| A: Core | 0 to 25 | None | None |

IEC 61300-3-35:2015 |

| B: Cladding | 25 to 115 | None | None | |

| C: Adhesive | 115 to 135 | None | None | |

| D: Contact | 135 to 250 | None | None | |

| E: Rest of ferrule | None | None | ||

End-Face Qualty (MM)

| Zone | Range (μm) | Scratches | Defects | Reference |

| A: Core | 0 to 65 | None | None |

IEC 61300-3-35:2015 |

| B: Cladding | 65 to 115 | None | None | |

| C: Adhesive | 115 to 135 | None | None | |

| D: Contact | 135 to 250 | None | None | |

| E: Rest of ferrule | None | None | ||

Mechanical Characteristics

| Test | Conditions | Reference |

| Endurance | 500 matings | IEC 61300-2-2 |

| Vibration | Frequency: 10 to 55Hz, Amplitude: 0.75mm | IEC 61300-2-1 |

| Cable retention | 400N (main cable); 50N (connector part) | IEC 61300-2-4 |

| Strength of coupling mechanism | 80N for 2 to 3mm cable | IEC 61300-2-6 |

| Cable torsion | 15N for 2 to 3mm cable | IEC 61300-2-5 |

| Fall | 10 drops, 1m drop height | IEC 61300-2-12 |

| Static lateral load | 1N for 1h (main cable); 0.2N for 5min (ranch part) | IEC 61300-2-42 |

| Cold | -25°C, 96h duration | IEC 61300-2-17 |

| Dry heat | +70°C, 96h duration | IEC 61300-2-18 |

| Change of temperature | -25°C to +70°C, 12 cycles | IEC 61300-2-22 |

| Humidity | +40°C at 93%, 96h duration | IEC 61300-2-19 |

12 Core MPO MTP TO LC Harnesses Cables SM OS2 Cable structure