What Is 96 Core Optic Splice Joint Closure 2 in 2 out Horizontal Types?

96 Core Optic Splice Joint Closure Horizontal Types 2 in 2 out F001 are used to distribute, splice, and store the outdoor optical cables which enter and exit from the ends of the closure. There are two connection ways:direct connection and splitting connection. They are applicable to situations such as overhead, man-well of pipeline, embedded situation etc. Comparing with terminal box, the closure requires much stricter requirement of seal.

Features

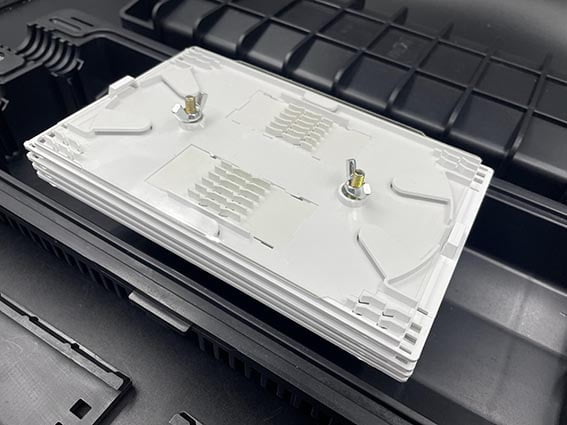

- The closure casing is made of quality engineering PP plastics, and of good performance of anti-erosion against acid and alkali salt, anti-aging, as well as smooth appearance and reliable mechanical structure.

- The mechanical structure is reliable and has the performance of resisting wild environment and intensive climate changes and serious working environment. The protection grade reaches IP68.

- The splice trays inside the closure are turn-able like booklets, and have adequate curvature radius and space for winding optical fiber to make sure the curvature radius for optical winding 40mm.Each optical cable and fiber can be operated individually.

- The closure is of small volume, big capacity and convenient maintenance.The elastic rubber seal rings inside the closure are of good sealing and sweat-proof performance.

Applications

- Used for direct transmission of outdoor cable in aerial、duct and direct buried application.

- Used for branching connection and protect the joint.

Standard Accessories 96 Core Optic Splice Joint Closure 2 in 2 out Horizontal Types

- Metal spanner:1pcs

- Metal hanger :4pcs

- Sealing rubber strip:2pcs

- Insulating tape:2pcs

- Metal ring :4pcs

- Plastic ring:4pcs

- Plastic plug:14pcs

- Heat-shrink sleeve:1.2mm*60mm 96pcs

Dimensions and Capability 96 Core Optic Splice Joint Closure 2 in 2 out Horizontal Types

- Dimensions A*B*C(mm) : 480*155*110

- Max Capacity:Splice 96 Fibers (8 trays,12 core/tray)

- Number of Cable Entrance/Exit:2 in 2 out

- Diameter of Cable:φ 26mm

- Weight : 2.3 kg

Factors to Consider When Choosing Fiber Optic Closure

The optical network structure is often complex, especially the optical access part has unique requirements to function well. A reliable fiber optic splice closure will eliminate lots of unnecessary issues. For example, for the network distribution system, a long-lasting, durable optical closure can avoid frequent check of the access link part. And as the network reaches the distribution stage and drop lines, a splice closure that allows adding more connections will be great. The following factors will help you to choose the right fiber optic splice closures and protect the fiber optics in your network.

1. Cable Compatibility

A good fiber optic closure shall be capable of accepting any fiber optic cable as specified in the tender document. Thus, it is vital to figure out cable compatibility before selecting the right closure type. The design of fiber optic splice closure changes with the application areas. Therefore, a fiber optic splice closure for aerial will have a different design from that used for the underground application.

2. Numbers of Cable Ports

The cable port is also known as the cable entrance capacity. The number of ports in a fiber optic closure reflects its capacity to handle the number of cables. The cable entrance capacity of a fiber optic splice closure refers to the number of ports available for terminating cable within the closure. The number of ports provided in a closure depends on factors such as the network capacity and the number of cables employed in the network. Usually, in an attempt to reduce the physical size of high-capacity closures, smaller ports shall be utilized for branch cables and drop cables.

3. Termination System

Before choosing the splice closure type, the cable termination system should be designed to provide sufficient mechanical strength between the cable and closure to ensure its performance throughout the lifetime. The materials used for fiber optic splice closures shall also be capable of minimizing or negating the effects of relative motion between cable components because the materials used in optical fibers are easy to thermal expansion and contraction.

4. Types of Splices

The splice trays within the fiber optic splice closure can’t hold enough cables if the cables do not be spliced properly. Usually, ribbon or mechanical splices have a larger size, which may lead to capacity loss of the closure trays. A suitable configuration of the splices can avoid installation problems and help improve performance. Therefore, the types of splices should be considered when choosing a fiber splice closure.

5. Bonding & Grounding

Proper bonding and grounding of conductive elements of the optical network shall be provided for the safe deployment and operation of the network.

6. Hardware and Accessory

Aerial fiber optic closures may need to hang on the messenger wire depending on the network configuration. Or they may be attached to the pole. In both cases, extra hardware is required along with the closures. The hardware or accessories to attach and secure should be able to bear wear and tear and also environmental stresses.

7. Cable Management

Keeping a low bend radius in fiber cables installations is important. The link performance may be affected if this factor is ignored. A fiber optic closure that can support well cable management should be considered when making a choice. And splice closures that allow for easy installation can eliminate excessive stress or damage during handling.

Tom –

96 Core Optic Splice Joint Closure 2 in 2 out Horizontal Types